- Materials - Constructed to provide rugged and reliable service under the most severe and demanding conditions.

- Yellow Color Tube - Assures the user that they are using a WASTEC designated Piranha Hose Product.

- Polyolefin or Seamless Thermoplastic Tube - Provides maximum resistance to hydrolysis.

- High Tensile One or Two Synthetic Fiber Braids - Contributes to low volumetric expansion and eliminates loss of strength from moisture absorption.

- Abrasion Resistant Polyether-Urethane - Polyurethane cover provides exceptional cut, abrasion and fungus resistance.

- Slither™ Cover - Cover is ultra slippery; allows hose to manoeuvre around and through difficult sewer bends.

- Pressure Testing - All Piranha factory-assembled hoses are 100% pressure tested.

- Reel Installation - Ideal for truck and trailer mounts.

-

Piranha Series Slither™ Cover Jetting/Lateral Line Hoses are designed with an ultra slippery cover which allows the hose to manoeuvre around and through difficult sewer bends. Hoses are available in any length, standard male x male fittings; male swivel and female are available. Orange hose is 2500 psi. Blue hose is 3000 psi. A yellow polyolefin tube, single high tensile synthetic fiber braid reinforcement and abrasion resistant orange polyether-urethane cover. Features & Advantages:

-

Piranha Series Slither™ Cover Jetting/Lateral Line Hoses are designed with an ultra slippery cover which allows the hose to manoeuvre around and through difficult sewer bends. A yellow polyolefin tube, single high tensile synthetic fiber braid reinforcement and abrasion resistant orange polyether-urethane cover. Orange hose is 2500 psi. Blue hose is 3000 psi. Features & Advantages:

- Materials - Constructed to provide rugged and reliable service under the most severe and demanding conditions.

- Yellow Color Tube - Assures the user that they are using a WASTEC designated Piranha Hose Product.

- Polyolefin or Seamless Thermoplastic Tube - Provides maximum resistance to hydrolysis.

- High Tensile One or Two Synthetic Fiber Braids - Contributes to low volumetric expansion and eliminates loss of strength from moisture absorption.

- Abrasion Resistant Polyether-Urethane - Polyurethane cover provides exceptional cut, abrasion and fungus resistance.

- Slither™ Cover - Cover is ultra slippery; allows hose to manoeuvre around and through difficult sewer bends.

- Pressure Testing - All Piranha factory-assembled hoses are 100% pressure tested.

- Reel Installation - Ideal for truck and trailer mounts.

-

The AquaJet has a very compact design. It fits almost every lightweight van and pick-up, such as Toyota Hiace, MB Vito, VW Transporter, VW Caddy, Peugeot Partner. Alternatively it could also be fitted to a small pantech. The machine leaves a maximum loading space inside the van for storing other tools and equipment without exceeding the maximum payload weight. The machine can be fitted very easily. The AquaJet is suitable for unblocking and cleaning drains and sewers up to 350 mm.

-

The Rioned MultiJet is a high pressure jetting trailer designed and built with our latest jetting technology and is suitable for unblocking and cleaning drains and sewers up to 600mm.

- Robust and durable

- Designed for intensive use

- Patented 90° + 180° pivoting high pressure hose reel

- Very stable road holding

- Low noise level

-

The MiniJet is a professional high pressure jetting machine, that can be taken everywhere without problems. It is suitable to clean drains from 25 – 100 mm.

- Professional HP jetting machine

- Powerful pump

- Easy to transport

- With separate detachable motor / pump unit

- For drains from Ø 25 - 100 mm

- Ergonomic

-

Out of stockWith the FLEXXY barrier, you can effortlessly close access to dangerous and restricted areas. FLEXXY is made with hard plastic, is very light and compact and can be erected in a few seconds. The outside “shell type” shoulders functions as both ground support and a transportation case.

-

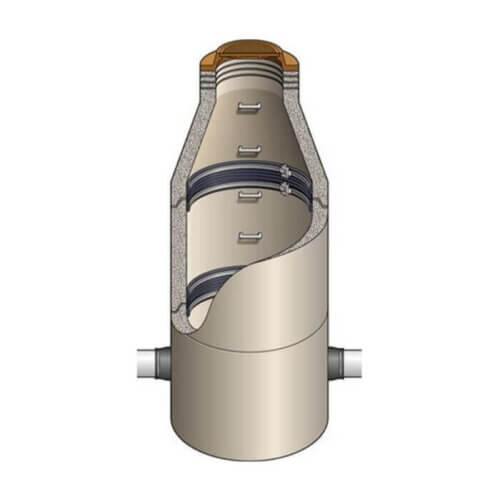

Eliminates Inflow and Infiltration. The grade adjustment area of the manhole is the first to suffer deterioration caused by freeze/thaw cycles, traffic loading, thermal expansion and contraction of the surrounding pavement and other external forces. The solution for this problem is the DRAIN Flexrib Manhole Seal. Benefits:

- Creates a watertight seal between the frame casting and top of the manhole cone

- Allows the Seal to move vertically and/or laterally while maintaining a watertight seal

- Made from a premium quality rubber compound and available in four widths.

- Patented Waveband technology creates a more effective seal by concentrating the compressive force of the expansion band. The rubber is “captured” between the band and the concrete.

-

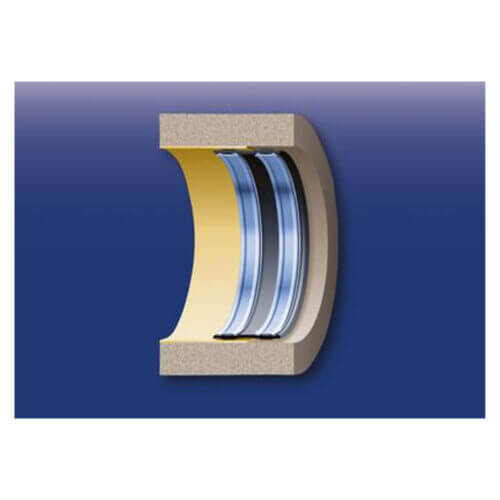

Designed to restore joint integrity. Pipe and manhole joints generally experience higher ground water pressure than the grade adjustment area of a manhole. When infiltration occurs due to deflection, offset or corrosion, the Internal Joint Seal is specifically designed to reestablish watertight conditions. A = The portion of the seal which covers the pipe or manhole defect B = The complete width of the seal once installed (includes the band compression area) Benefits:

- Can be used in concrete, HDPE and most other types of pipe

- Installs easily with torque wrench and socket

- Extension seals available to expand coverage area

- WedgeLock expansion bands create a watertight seal capable of withstanding 10 m of external head pressure

-

Prevents infiltration between Liner and Host Pipe. The Drain Liner End Seal utilizes the patented Slotted Band® to provide maximum sealing force with a minimum reduction in pipe diameter. This unique design captures the rubber and compresses it against the host pipe and new CIPP liner creating a permanent mechanical seal. The patented Slotted Band is constructed from a single piece of Stainless Steel (EN 1.4307) precisely rolled to match the diameter of the CIPP liner. The unique shape of the Slotted Band provides the maximum amount of strength and sealing force with the least possible thickness. The band is then expanded using a hydraulic expansion tool. As the band expands the integral latching mechanism progresses from slot to slot, positively locking on each one until the next one is reached. There is an audible click created by the spring/rubber interaction as the band is expanded into place. Benefits

- Manufactured from EPDM Rubber and Stainless Steel to withstand the harsh sanitary sewer environment.

- Complies with material property requirements of ASTM C923

- Quick and easy to install

- Eliminates Infiltration/Exfiltration between the Liner and Host Pipe

-

Resin systems for full rehabilitation and sectional renovation of pipes and sewers. Trelleborg Pipe Seals manufactures high-quality resin systems for the rehabilitation of sewers and wastewater pipes. Three basic resin types are available:

- EpoxyResins for CIPP lining applications; and

- SilicateResins for lateral connection repairs and patches. Available in fast WOI, Winter and Summer.

Trelleborg Resin Systems

Two-component resin mixture made of component A (synthetic resin) and B (hardener) Trelleborg EPROPOX resins are used in the Trelleborg DrainLiner methods (CIPP liners) as well as in the Trelleborg DrainLCR methods. To be able to meet the varied needs of our installers, we developed a multitude of epoxy resin systems geared to specific applications. These systems stand out for their improved mechanical properties, e.g. flexural modulus, flexural stress, TG and reduction factor, which are considerably higher than those found in conventional resin systems. Thanks to their viscosity and surface tension, all EpoxyResin systems are extremely easy to handle, penetrate carrier materials quickly and provide very good mechanical properties and chemical strengths after final cure. Both filled and unfilled resin systems are available, depending on the particular application.Silicate Resin Systems

These resin systems are used especially for lateral connection and short repairs (DrainLCR and DrainPacker). They are easy to handle and quick to install and stand out for their good mechanical properties and chemical resistance after final cure. The patented two-component resin mixture is made up of the components B (resin) and A (hardener) at a mixing ratio of 2:1 (by volume). Benefits:- Cures at ambient temperature within about 1 to 3 hours (cure times can be controlled and adjusted)

- Excellent performance both at extremely high and at extremely low temperatures

- Very good resistance to acids and caustics (pH 1 - 13.5) after final cure

- High temperature resistance of short/CIPP liner after final cure

- No volatile organic compounds (styrene free)

- Excellent adhesion to many pipe materials like vitrified clay, plastic, steel etc. with a close frictional and positive fit to HDPE pipes

- Virtually no shrinkage (<0.6%)

- Can be used at a wide range of ambient temperatures

- Excellent performance both at extremely high and at extremely low temperatures

- Expected service life of more than 50 years as proven by 10,000-hour test

- The cured resin is self-extinguishing and can thus be used in critical areas such as airports and tunnels

- Tested by independent bodies (IKT - Gelsenkirchen, WRc UK)

- In compliance with international standards such as DIBt, ASTM, WIS and DIN EN

-

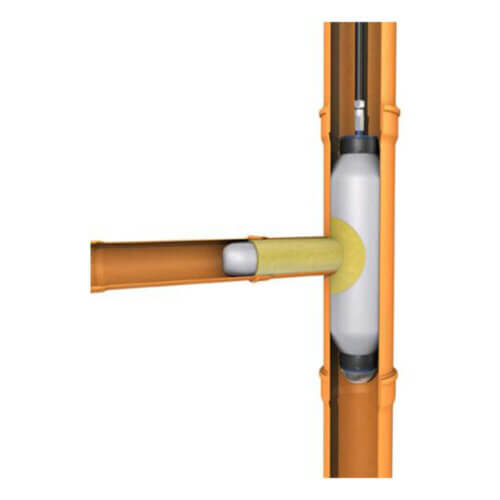

Method for the Sectional Renovation of Lateral Junctions and Pipes in the Main Sewer Line Main pipe: DN 130 to DN 600 Lateral pipe: DN 100, 125, 150 and 200 at 30° to 90° The DrainLCR-S system is used to repair and permanently seal main/lateral interfaces and connections up to 500 mm from the mainline down into the lateral. The system can use either an LCR-S hat profile or an LCR-S liner. The main-to-lateral interface in the main pipe is sealed only by the rim of the LCR-S hat profile, while the LCR-S liner in the main pipe is designed as a short liner. Benefits:

- Reliable to install: 1. Inversion is not possible until positive engagement of the pathfinder. 2. The signal will not sound until complete inversion.

- Technical advance: Only the inversion process allows pipe bends and offset joints to be relined.

- Meets practical needs: Successful repairs are possible with little equipment needs only, even in the presence of groundwater.

- Price advantage: Low investment cost, because you need to buy just the packers actually required.

- Practical: The low-weight mobile unit with low space requirements can be placed even in a small car.

- Flexible: It is also possible to use air push rods or a carriage.

- Accessibility: The LCR packers can be folded as required inside the manhole.

- User-friendly equipment: The LCR packers can be converted to other sizes as required.

-

New Method for the Lateral Connection Repair of Underground House Sewers and Downpipes in Buildings Main Pipe DN 100 - DN 200 Lateral DN 50 - DN 200 (at 30° - 90°) Trenchless repairs of lateral connections are rather tricky jobs to do. Many commonly available packer systems cannot cope with pipes having diameters of rarely more than DN 100 – and sometimes even additional pipe bends. Until the recent past, no repair system in the DN 100 to DN 150 range had been available for sealing junctions of down pipes, house sewers and lateral pipes, i.e. pipe sizes of DN 50 to DN 150. With LCR-B ("B” stands for building), Trelleborg managed for the first time ever to scale down to lateral and house sewer sizes the LCR-S method (“S" stands for sewer) known from main line rehabilitation, in which a packer is used to invert a fibreglass "hat" profile into the main/lateral interface. As an alternative to the specifically developed hat profile, it is also possible to use a liner of the appropriate size. The LCR-B hat profile in the main pipe seals the interface between the two pipe systems with its rim only, whereas the LCR-B liner is designed as a short liner in the down pipe or house sewer. The standard lateral repair length is 300 mm - the new LCR-B packer model allows a maximum repair length of 1300 mm. The LCR-B liner and hat material is suitable for steam curing and has high mechanical properties and very good sealing capabilities. In order to reduce the curing time, Trelleborg Pipe Seals is offering a steam generator (SteamGen V3). Behaviour in bends Depending on the actual host pipe run or on wrinkles formed in the installed liner: 45° for DN 100 main line 90° for DN 125 or larger main line Wall thickness of 2 to 3 mm Benefits

- Meets practical needs: Successful repairs with little equipment needs only, even in the presence of bends.

- Price advantage: Low investment cost, because you need to buy just the packers actually required.

- Practical: The low-weight mobile unit with low space requirements can be placed even in a small car.

- Flexibility: The job can be done with air push rods; no carriage needed.

- Accessibility: The LCR-B packers can be folded as required.

- No risk of fire: The resin system used for the liner system is self-extinguishing.