One System Configured to suit your needs!

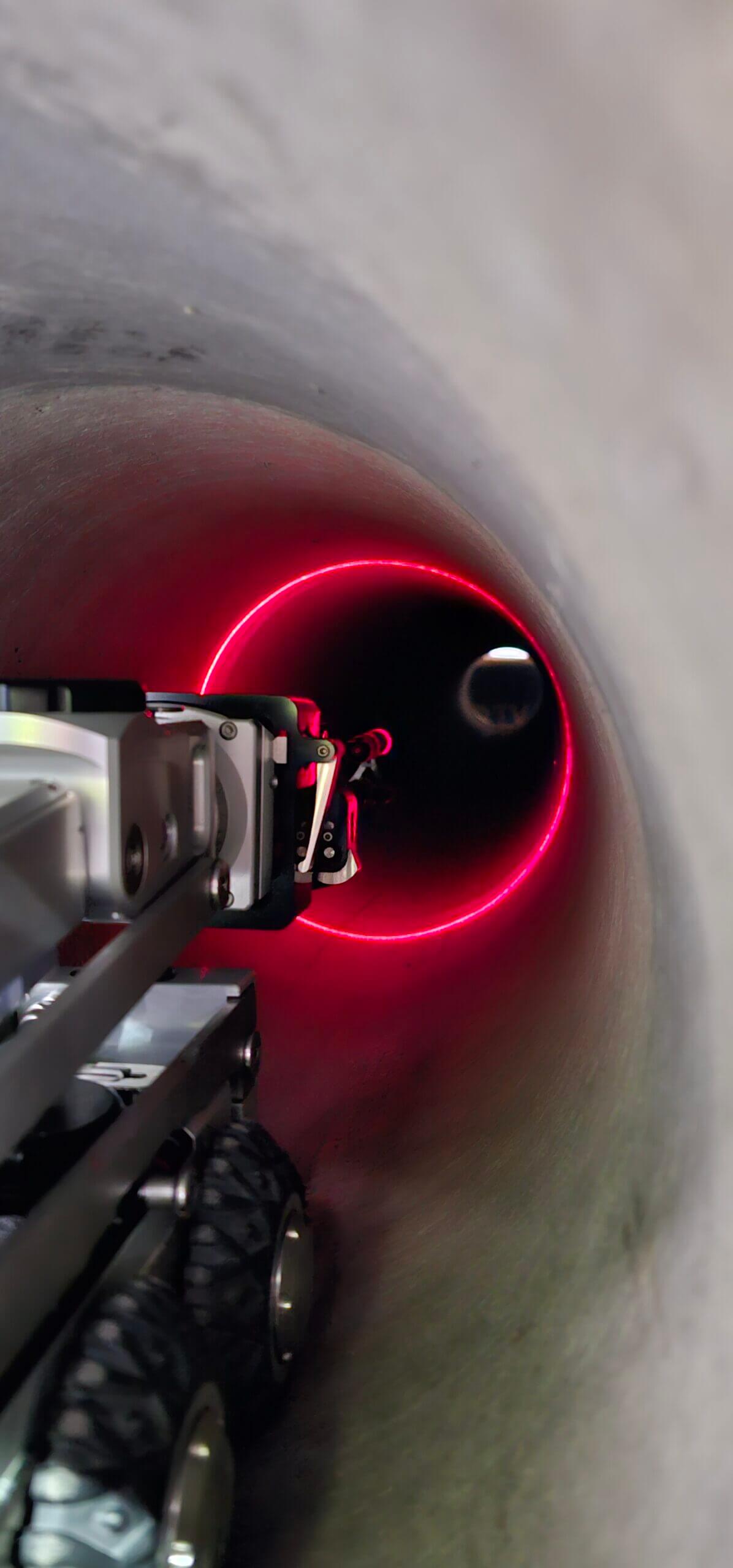

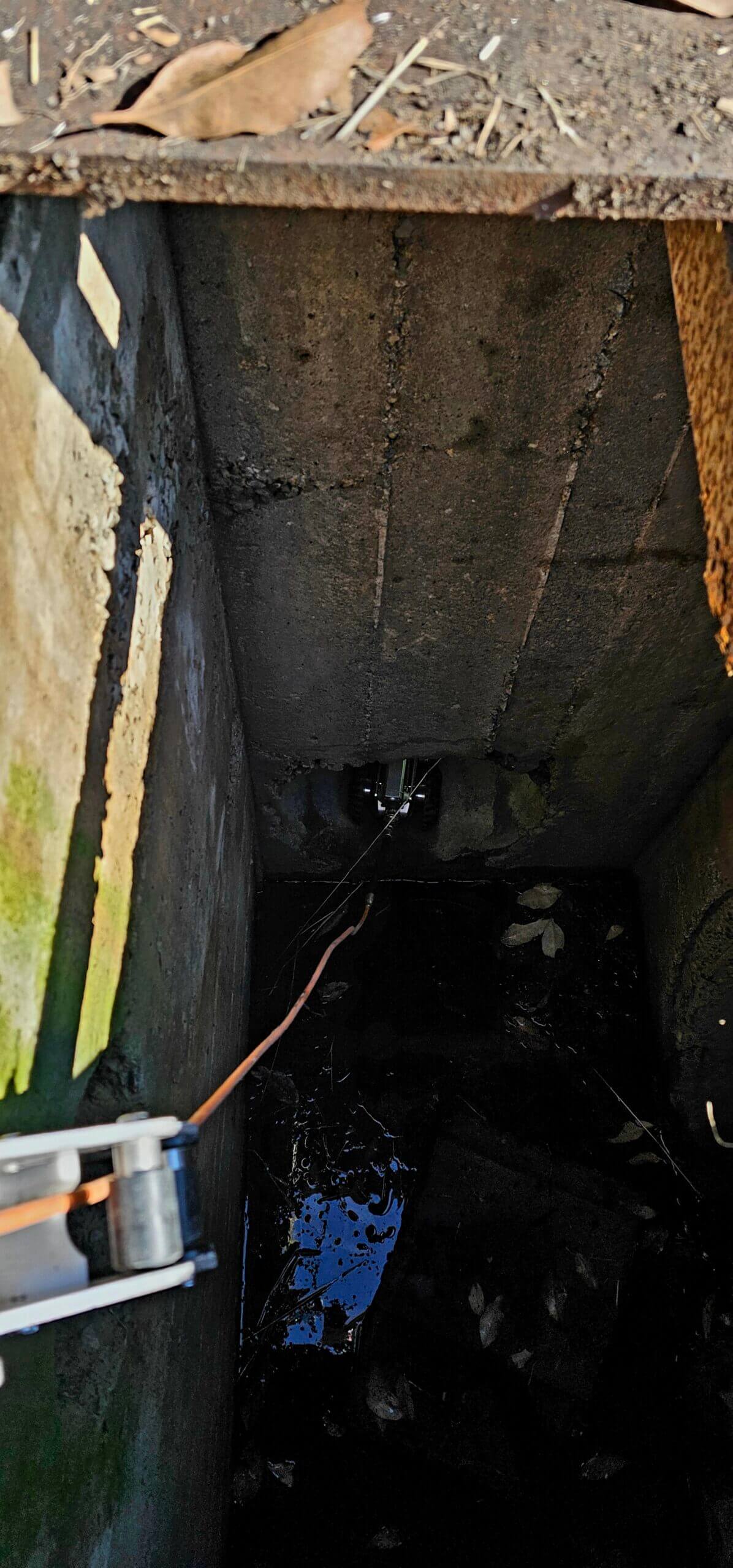

The user-friendly ROVION®-pipeline inspection system has successfully completed tests out in the field. It is scalable and all components are fully compatible with each ot

her. Depending on the combination of the high-quality components inspections for pipe diameters ranging from 100 to 2000 mm can be performed.

CAMERAS

High compatibility, robust design, wide selection of inspection cameras: axial camera, pan & tilt head cameras, camera with fisheye lens, shaft inspection camera with rotation unit.

CRAWLERS

Inspection range DN 100 – DN 2000 Sophisticated construction, aesthetic design, modular accessories for different inspection tasks.

CABLE REELS

An enormous range of application possibilities and high-quality workmanship. Extremely robust camera cable, operating ranges up to 500m, with both manual and automatic reels available with remotes.

FEATURES

- High-resolution Zoom camera

- Suits pipes 95mm to 2000mm

- Cable length 200m to 500m

- Modular design for future growth and expansion

- Inspects all types of pipes to WSA & NZPIM standards communicates directly with WinCan reporting software

- Multiple configurations available to suit any operational needs

- Fully supported by SECA’s German factory trained technicians in Sydney, Melbourne, Brisbane, Auckland & Christchurch

VISION CONTROL VC500

MOBILE CONTROL PANEL

The ROVION® pipeline inspection system is equipped with the VC500 central control panel and the VISIONREPORTII software. This control panel can also be used with other iPEK systems e.g. the AGILIOS® push camera system.

DCX5000

OPERATOR PANEL CUSTOM-BUILT VEHICLES & CORE CONTROL UNIT.

The DCX5000 Control is the core control unit of custom-built vehicles equipped with the ROVION system.