Certified pipe rehabilitation solutions from the drain to the treatment plant

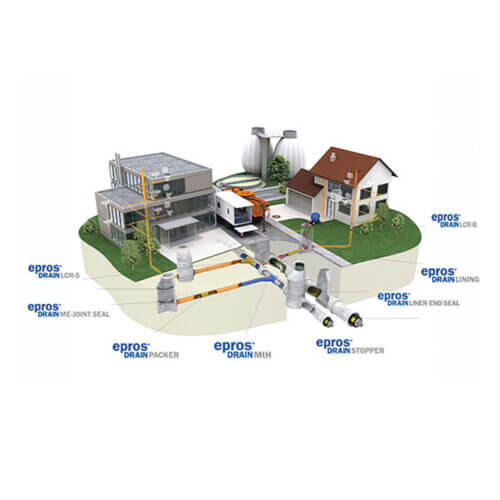

The DrainSystems range covers almost the entire scope of necessary repair and renovation measures in a pipe system. There are sophisticated solutions to almost any problem:

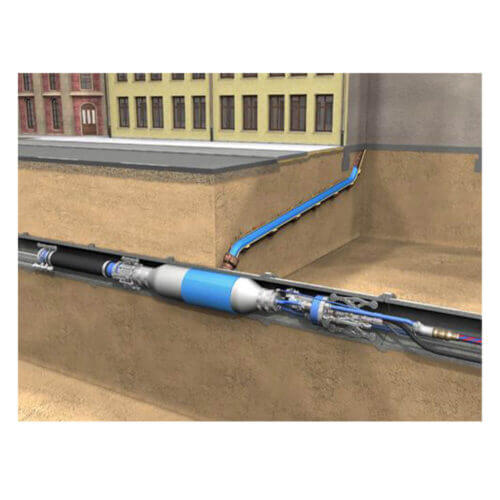

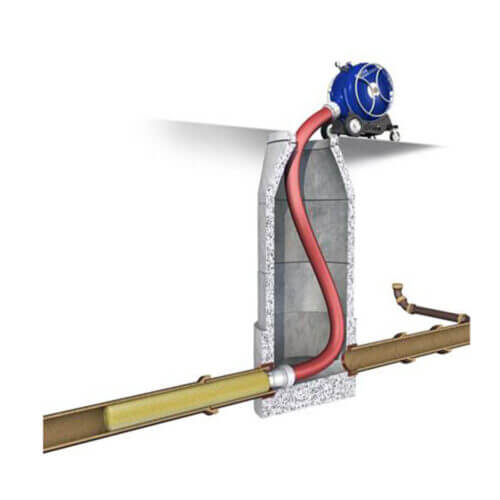

Trenchless methods (“no-dig technologies”) are a both practical and economical alternative to full-scale replacements especially in industrialised nations, large cities and agglomerations having a dense network of sewers. In contrast with conventional repair techniques involving digging up the streets, they contribute a lot to energy savings and climate protection by avoiding dust and CO² emissions from construction operations and traffic jams.

- No social disruption (roads, pedestrians)

- No nuisances for residents/neighbours from noise, smell, or dirt

- No or just brief disruption of operations (industrial plants)

- Low overall cost

- Potential to prevent full rehabilitation or full renewal, and thus to avoid essentially higher costs, by early renovation (preventive action)

- Compliance with current standards and regulations by certified methods

- High rehabilitation potential by sectional repair of part lengths or full renovation of longer pipe runs

Due to its unique product range of certified building products in the field of trenchless pipe rehabilitation solutions, Trelleborg has developed a unique selling proposition from which customers and users can also now profit.

Please contact us for price & availability.