-

Drain Cleaner Nozzles or Drain cleaning tools from Warthog offer superior drain cleaning. Warthog nozzles are engineered to handle the roughest sewer cleaning applications. Please call or enquire online for price & availability.

-

ONE SYSTEM FOR MULTIPLE APPLICATIONS

A streamlined and economical system that swiftly eliminates root intrusions, trims protruding taps, restores lateral connections, applies spot repair systems. It clears stubborn grease, excess concrete, calcium, and scale deposits from pipes and service laterals ranging from 150mm to 1000mm below ground. -

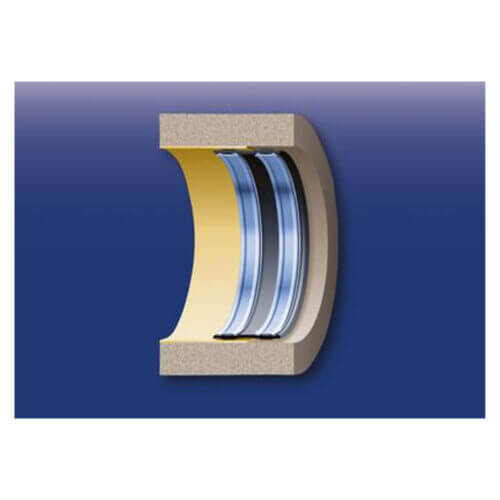

Cherne i2-Series plugs are designed to meet the size and expansion needs of Australian markets, offering enhanced safety and performance with a robust, optimised design.

Available in various sizes, these compact plugs are made from premium natural rubber with full body cording, ensuring reliable, high-quality performance even in constrained spaces.

Please contact us for price and availability.

-

From grates to maintenance holes, you encounter a wide range of covers in your daily work. When you need a tool that can handle the heavy lifting, rely on T&T Tools Inc. Experience the convenience of our innovative Lid Sling Hook. This pocket-sized utility tool is incredibly compact and portable, designed by experienced field technicians to work with various maintenance hole covers, grates, and handhole lids. The Lid Sling Hook is ideal for professionals like utility locators, field technicians, inspectors, and surveyors. Common Uses: The Lid Sling Hook is perfect for lifting and pulling manhole covers, vault covers, storm grates, and a variety of other tasks. Estimated price $215 (plus GST)

Complete the form to pre-order today!

-

ASSET MANAGEMENT SOFTWARE FOR WASTE WATER INFRASTRUCTURE WinCan VX is the core of the entire WinCan product family. It offers the core functionality you need to collect pipe inspection data, organize it into a database, and generate inspection reports that graphically display the pipe and its defects. WinCan VX also allows you to manage data in the office post-inspection, share it with clients using free viewer software, and export it in a variety of formats. Various report templates present a concise summary of asset condition, and can be fully customized to individual needs.

-

ROVION – CCTV Inspection System NOW IN HD!

Australia & New Zealand’s most popular CCTV pipe inspection system. From small pipes to large pipes ROVION® has you covered. -

Lay the foundation for solid growth towards becoming a Sewer Inspection Company

The latest AGILIOS generation has been developed with the goal to perform “Inspections in all situations”. -

OPTIMIZED For Productivity The Quickview airHD is the only zoom survey camera to offer these features to boost your productivity, detail and safety:

- Remote tilt adjustment

- HD video

- Cable-free (wireless) design

- Touchscreen tablet control

- In-manhole view centering

- Hands-free stabilization

- Quad-Haloptic light engine maximizes viewing distance and side wall illumination.

- HD camera delivers 4X more detail than SD.

- Low-lux imager captures enhanced detail from darker/farther regions.

- Touchscreen tablet interface allows control, viewing, annotation and playback.

- For optimum centerline viewing, camera height and tilt adjust remotely.

- Clamp-on bipod allows hands-free operation for maximum image stability.

- System components travel in compact, rugged roller case with telescoping handle.

- Collapsible pole fits in pick-up bed, but extends to 16’ (or longer with extensions).

- Rechargeable, swappable 4-hr lithium-ion batteries keep you inspecting all day.

- WiFi-based control and video transmission means no cables.

-

Each vehicle fit-out is designed to suit your individual needs. Variables such as vehicle size, system configuration, load capacities, storage requirements, etc., having to be taken into consideration when planning the design. Contact us to find out about what vehicles we can fit-out and any other options available. The videos below are of our standard fit-out of a Mercedez Benz long wheeled base van. Other branded vans and sizes can also be done. *fit-outs are limited to SECA camera system builds only.

-

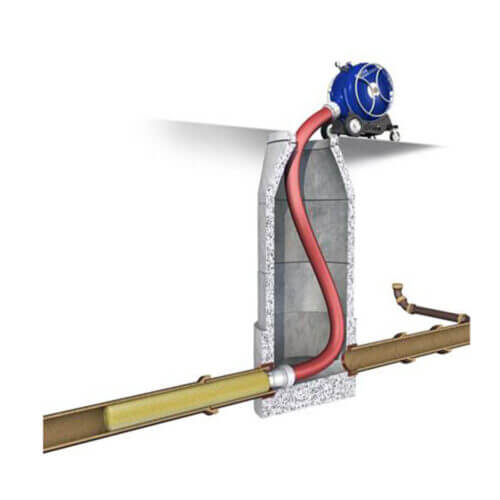

The MRT Blasting Unit is a fully automated and controllable water/granule blasting unit for preparation of manhole surfaces. The MRT Spinning Unit is a fully automated and controllable application head, used for rehabilitation and coating of manholes with Ombran MHP-SP. The time saving compared to hand application is up to 80%.

-

Universal model with rectangular base ideal for lifting, moving and repositioning the majority of covers and grilles in cast iron and ferrous materials. The handle is telescopic and folding, minimising the space needed. The exclusive configuration gives versatility of use in four ways to fit the majority of lifting/repositioning operations. The plate, with 16 powerful neodymium magnets assures a lifting force of 300kg with a weight of only 7kg.

-

The Model C Sectional Drain Cleaner is the best unit available for tougher blockages such as tree roots and for longer runs in main sewer lines.

-

The Electric Eel Model CT features unique variable speed motor control that gives the operator maximum cable control and exceptional cleaning power from 75 to 350 RPM with constant torque.

-

The Model 325 Gasoline powered sewer cleaner is designed to clean 100mm to 355mm diameter lines for distances up to 152M and is ideal for industrial, contractor, and municipal use.

-

One of the major benefits of mechanical plugs over pneumatic plugs is mechanical plugs can be used in long - term applications. Unlike pneumatic plugs, which can lose air pressure over time, mechanical plugs do not use air pressure, resulting in a more secure seal.

- Made of heavy-duty aluminium

- Neoprene “O” ring (chemical resistant)

- Sizes 6" - 12" sized for concrete, clay, and SDR 26 & 35 pipe

- Sizes 15" & 18" sized for concrete & clay pipe sizes only

This product is a special order. Please contact us for price and availability.

-

Exclusively from Cherne, Multi-Size High Pressure Plugs. Features:

- Multi range use (6 plugs will cover pipe sizes from 4" to 32")

- Unlike single sized products, Cherne’s new HP plug has the rubber and metal bonded eliminating fears of separation or rolling off resulting from high backpressures.

- Aramid fiber construction

- Optimized design using steel, aramid and natural rubber to ensure longevity and robust construction

- Cherne recommends using water to inflate these new high pressure plugs

- Removable and field repairable hardware

- Safety/Over-inflation device

- Made in USA

This product is a special order. Please contact us for price and availability.

-

Protective Sleeves Greatly reduces possibility of damage to plug due to debris and sharp objects in the pipe. The protective sleeve also protects plugs when the pipe is degraded. Works particularly well in coastal areas where oysters and barnacles are present. Features:

- Extends plug life

- Eliminates superficial cuts on plugs

- Great for rental distributors & frequent users

- Maintains back pressure ratings

- Easy to install without special tools

This product is a special order. Please contact us for price and availability.

-

Deflection GaugesDeflection Gauges (mandrels) are used to test flexible sewer pipe for out-ofroundness or deflection per ASTM specifications D3034 and F679. This testing ensures that flexible pipe has been properly bedded and backfilled (ASTM D2321) to give optimal performance.Both steel and aluminum gauges utilize a nine arm design to ensure the pipe is tested accurately. This design also allows gravel and debris to easily pass through.Other gauges can get hung up – causing a deflection test to fail, even though the pipe is within tolerance. Sized to .01" , both deflection gauge styles meet ASTM requirements.Aluminum Fin Style Deflection Gauge:

- Lightweight, corrosion-resistant

- Field-verifiable without a proving ring

- Assembles without tools

- All sizes fit through standard 24" manhole

- Fins for 4"-15" gauges have skid size equal to the nominal pipe size—gauge will meet regional codes and will not tip in the line

- Nine-fin design ensures testing accuracy

- Open design allows gravel and debris pass-through

- Durable, zinc-plated construction resists corrosion

- Conforms to mandrel sizing specifications—blade length is equal to or greater than the nominal pipe size

- Nine-arm design ensures testing accuracy

- Open design allows gravel and debris pass-through

- Used to verify deflection gauge sizes

- Standard sizes: 6"-15" SDR 35 5% deflection and 8"-12" SDR 35 7.5% deflection

- Custom sizes for 5"-18" also available

This product is a special order. Please contact us for price and availability.

-

Smoke Testing Smoke testing sewer systems was introduced in the early 1960’s as a method of identifying areas where extraneous water was entering sanitary sewer systems. Today, smoke testing is known to be a proven method of effectively identifying inflow (storm/ground water entry into sanitary sewer), connected roof and basement drains, yard drains, illegal taps, and storm sewer cross connections. Reducing inflow and infiltration saves costs from treating groundwater at wastewater treatment plants. The Environmental Protection Agency has instructed municipalities to eliminate inflow and infiltration into sewer systems. Smoke testing sewer systems is an effective way to accomplish this goal. Smoke testing is accomplished by isolating a section of sewer line and introducing smoke into the line utilizing a smoke blower and smoke-generating device. (Important: Notify all local authorities and citizens before conducting smoke tests! Cherne provides guidelines for properly preparing and announcing to the community that a smoke test will be conducted.) Lines are first isolated using pipe plugs. Then smoke is introduced into the sewer system. The test crew then checks buildings, roof vents, the street, and other areas that potentially could be a source of extraneous water and records those locations for corrective follow-up. Smoke Blowers Cherne offers the broadest line of smoke testing equipment available today. Our smoke blowers are available for either traditional “smoke bombs” or liquid smoke fluid. Available with Honda or Briggs & Stratton engines, our units generate up to 3,769 cubic feet per minute of airflow to quickly introduce smoke into the sewer system. Cherne’s blowers are made of lightweight cast aluminium and feature a 1/2" foam cell gasket to insure a leak-free seal on manholes and minimize vibration. The traditional smoke blower has a smoke bomb box holder, whereas the liquid smoke blower is supplied with a pressurized tank, hose and all components necessary to conduct the smoke test. Smoke Generating Devices Cherne Smoke Generating Devices (SGD), or “smoke bombs”, produce a thick, dense smoke that is highly effective for performing smoke tests. Smoke generating devices are timeproven, simple to use, and can be used by them selves or with most smoke blowers on the market today. Smoke Fluid Cherne’s Smoke Fluid also produces thick, dense smoke to effectively perform smoke tests. While Smoke Fluid requires some additional equipment to perform a smoke test, municipalities have found smoke fluid to be easy-to-regulate and has virtually an indefinite storage life.

This product is a special order. Please contact us for price and availability.

-

Air-Loc® Low Pressure Air-Testing system has been successfully used for pipeline testing for over thirty-five years. This method of testing pipelines has proven to be the fastest, most economical and accurate method for testing pipe. Air-Loc® Line Acceptance Kit. Used to perform a low-pressure air test from manhole to manhole. This is done by installing two Cherne Air-Loc plugs and using Cherne’s Air-Loc Panel to inflate the plugs and pressurise the pipeline. The test pressure is monitored for a predetermined amount of time for any decrease in pressure. If pressure drops less than 1 psi, the test passes. If a leak is detected, additional equipment is required to isolate the leak.

This product is available by special order. Please note that the pump is not included but can be purchased separately. For pricing and availability, please contact us.

-

Air-Loc® Leak Location Kit. If the line acceptance test indicates a leak in the sewer line, it becomes necessary to locate the leak(s) so that proper repairs can be made. A leak location (segment) test is accomplished by first stringing the sewer line using a Cherne Air-Loc Line Stringer or float line. Once strung, a winch cable is used to pull two Air-Loc Leak Locator plugs, which are attached together with an interconnect hose, through the pipeline in 22' intervals. Air is introduced between the plugs at each 22' increment until the test fails. Then, by moving the plugs back and forth, the leak can be isolated within two feet.

This product is a special order. Please contact us for price and availability.

-

The versatile Air-Loc® Fan Assembly can be used as a line stringer and smoke blower. Made from lightweight cast aluminium, this assembly includes a 5HP Honda or Briggs & Stratton engine and top mounted handles for easy manoeuvrability. Air-Loc® Fan Assembly Features:

- For use as a line stringer andsmoke blower

- Made of lightweight, cast aluminum

- Foam base minimizes vibration

- 30" Diameter base plate

- Honda or Briggs & Stratton engine

- Top-mounted handles for easy maneuverability

- Will string a 300' section of sewer line in under a minute without plugging the line

- Line stringer vacuum pulls a lightweight nylonparachute through wet or dry lines

This product is a special order. Please contact us for price and availability.

-

Positioned usually by a crawler and expanded pneumatically, Quick-Lock’s rehab sleeve provides structural, trenchless pipe repair with heavy-gauge 316 stainless steel, plus infiltration abatement with an EPDM rubber gasket. Quick-Lock is the solution for:

- Infiltration.

- Longitudinal cracks.

- Circumferential cracks.

- Holes.

- Separated joints.

- Offset joints.

- Abandoned laterals.

- Root intrusion.

- Quick-Lock sleeves in the smaller range are available in diameters ranging DN100–DN825, and in lengths of 400mm, and 500mm.

- DN825-DN1800 pipes are also catered for under confined space entry with the Quick-Lock Big seal.

- Multiple sleeves can be interleaved to perform longer repairs (JDL's) and for radial displacements (JDR's) choose the new Quick-Lock Flex seal.

-

The Quick-Lock BIG sleeve is a product for permanently and tightly sealing leaking pipe joints, radial cracks, and longitudinal cracks in large pipes and manholes of DN 800 and larger.

- The sleeve is 20 cm wide.

- The sealed area (between the circumferential seals) is approximately 12 cm.

- The materials used are permanently resistant in municipal wastewater systems.

- Their suitability must be ascertained for use in industrial or polluted wastewater.

-

Air-Loc® Manhole Testers provide the most efficient, accurate, and cost effective method of testing new, existing, and rehabilitated manholes. Vacuum testing identifies infiltration and exfiltration problems.

This product is a special order. Please contact us for price and availability. Vacuum pump not included.

-

Fast, safe and easy to use, a five-second test determines joint integrity. Cherne's Air-Loc® Joint Tester is designed to test large diameter, installed, pre-cast concrete pipe as described in ASTM C1103. Ready to test with water or air straight from Cherne's factory—no modifications are needed—the Air-Loc® Joint Tester also allows you to pre-test before backfilling. Capable of testing to 15 PSI air or 50 psi water. Features:

- Lightweight aluminium design allows for easy assembly in manholes

- Independent, adjustable wheels—easy to move

- Quick-connect control panel is simple to install and remove, plus the top-mounting feature won't interfere with laser usage

- Available with or without control panel and wheel kit

- Replacement end elements are available

- Recommended for testing pipe 21" and larger

This product is a special order. Please contact us for price and availability.

-

Air-Loc® Vacuum Pump Features:

- Choose a Honda or Briggs & Stratton engine–each with low-oil shut-off to prevent engine failure

- Heavy-duty frame with optional wheel kit

- Unbreakable aluminum filter jars

- Oil-free graphite vane pump for no-fuss lubrication

- Draws 10" Hg vacuum in about two minutes for a 15' deep manhole (18 CFM at 10" Hg)

- Converts standard air compressor into a vacuum source for testing manholes–draws a vacuum in minutes

- Vacuum Generator 460 delivers 14 CFM at 10" Hg

- Air compressor: minimum 7 CFM at 100 PSI

- Vacuum Generator 600 delivers 42 CFM at 10" Hg, meeting or exceeding the competition

- Air compressor: minimum 85 CFM at 100 PSI

This product is a special order. Please contact us for price and availability.

-

Air-Loc® leak locator plugs are designed for both low-pressure sewer line acceptance tests as well as leak location testing. Air-Loc® plugs can also be used to block flow by simply plugging the fill and readback ports. Features:

- Eye bolts on both ends

- Easy-to-use quick-disconnect hose connections

- Rupture discs available

- Cross-biased cording on sizes 375-750mm, 600-1050mm, and 1000-1500mm

- Color-coded inflation ports

- Removable air fittings

- Flexible internal hoses

- Field replaceable sleeves

This product is a special order. Please contact us for price and availability.

-

Hydrostatic Test Pumps are designed for pressure testing water lines and sewer force mains as prescribed by AWWA Standard C600 Installation of Ductile-Iron Water Mains and C605 Installation of PVC Pressure Pipe. Aqua-Loc® Hydrostatic Test Pumps are designed to be the most user friendly in the industry. Both Diaphragm and Piston Style pumps are available and come powered by either a Honda or Briggs & Stratton engine. Aqua-Loc® Hydrostatic Test Pump: Diaphragm Style – Features:

- Honda or Briggs Engine with low oil shut off

- Hypro® Twin diaphragm pump - 9.5 gpm/550 PSI

- Handles up to 10% chlorine solutions

- May be run dry

- Test pressures can be set from 100-550 psi

- Integral manifolds - eliminates leak points

- Enclosed gear reduction - excellent heat dissipation

- Pulsation dampener - no need to surge tank

- Heavy-duty frame

- Hydraulic quick-disconnect - brass, swivel fitting

- Inline strainer - easy to clean clear bowl

- Clear hose - flow verification

- Silicone filled test gauge w/stainless steel case

-

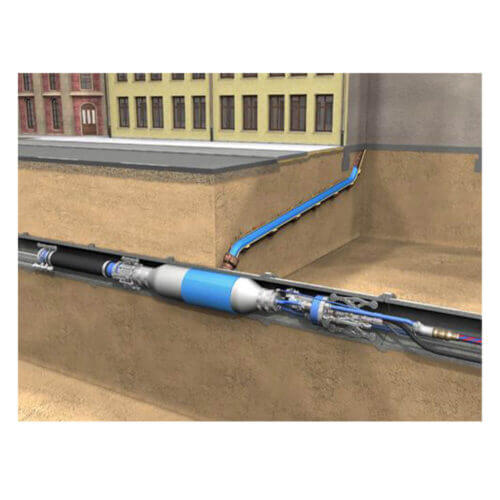

Full-Length Sewer Rehabilitation of Main- and House Sewer DN 30 - DN 1000 by Inversion method The DrainLiner method is best suited for the complete renovation of buried damaged gravity sewer pipes and pressurized pipelines. Perfectly matched and partly proprietary components ensure optimal results in the lining of:

- House sewers and lateral pipes

- Pipes inside buildings

- Main lines in the public area

- Leakage with or without groundwater infiltration or exfiltration at pipe joints, pipe walls, lateral junctions etc.

- Offset pipes, cracks and debris, ruptures

- Mechanical wear

- Corrosion

- Efficient time-saving installation

- Repairs damage in the pipe and joint regions even against strong infiltration.

- Enables installers to close obsolete lateral junctions.

- Repairs circular and egg-shaped pipes made of concrete, asbestos cement, plastics (PVC, PP, HDPE), cast iron, ductile cast iron, reinforced concrete and vitrified clay.

- Repairs entire pipe runs with size changes in between

- Long service life due to high-quality materials

-

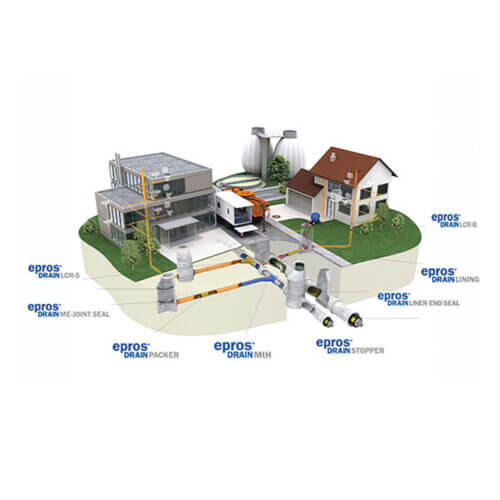

Certified pipe rehabilitation solutions from the drain to the treatment plant The DrainSystems range covers almost the entire scope of necessary repair and renovation measures in a pipe system. There are sophisticated solutions to almost any problem: Trenchless methods (“no-dig technologies”) are a both practical and economical alternative to full-scale replacements especially in industrialised nations, large cities and agglomerations having a dense network of sewers. In contrast with conventional repair techniques involving digging up the streets, they contribute a lot to energy savings and climate protection by avoiding dust and CO² emissions from construction operations and traffic jams.

- No social disruption (roads, pedestrians)

- No nuisances for residents/neighbours from noise, smell, or dirt

- No or just brief disruption of operations (industrial plants)

- Low overall cost

- Potential to prevent full rehabilitation or full renewal, and thus to avoid essentially higher costs, by early renovation (preventive action)

- Compliance with current standards and regulations by certified methods

- High rehabilitation potential by sectional repair of part lengths or full renovation of longer pipe runs

-

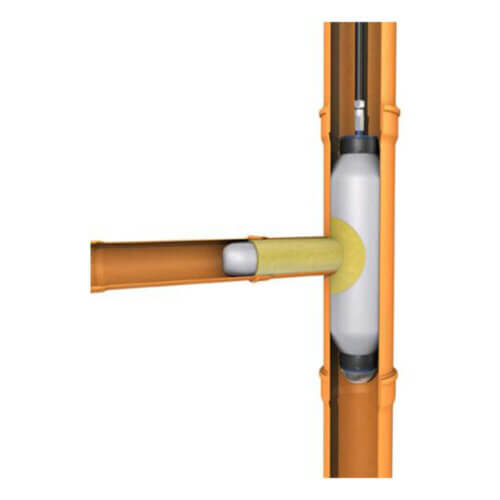

The unique Main to House sewer lining system Trenchless Rehabilitation system for the sealing and stabilizing of lateral connections and the lateral pipes from the main sewer to the house - based on the CIPP Lining technology. The benefits at a glance:

- No-Dig method

- No need to enter private property

- Max. rehabilitation length: 30 m / 98 ft

- Max. line distance between access manhole and lateral junction: 150 m / 492 ft

- Connection angle: 30° - 90

- Easy to position

- Negotiates bends up to 90°

- Excellent mechanical properties, exceeding requirements of ASTM

- 100% steam resistant

- Packer Type 0 : DN 135 - DN 150 | 5" - 6"

- Packer Type I : DN 200 - DN 225 | 8“ - 9“

- Packer Type II : DN 250 - DN 350 | 10" - 14"

- Packer Type III: DN 400 - DN 600 | 16" - 24"

-

New Method for the Lateral Connection Repair of Underground House Sewers and Downpipes in Buildings Main Pipe DN 100 - DN 200 Lateral DN 50 - DN 200 (at 30° - 90°) Trenchless repairs of lateral connections are rather tricky jobs to do. Many commonly available packer systems cannot cope with pipes having diameters of rarely more than DN 100 – and sometimes even additional pipe bends. Until the recent past, no repair system in the DN 100 to DN 150 range had been available for sealing junctions of down pipes, house sewers and lateral pipes, i.e. pipe sizes of DN 50 to DN 150. With LCR-B ("B” stands for building), Trelleborg managed for the first time ever to scale down to lateral and house sewer sizes the LCR-S method (“S" stands for sewer) known from main line rehabilitation, in which a packer is used to invert a fibreglass "hat" profile into the main/lateral interface. As an alternative to the specifically developed hat profile, it is also possible to use a liner of the appropriate size. The LCR-B hat profile in the main pipe seals the interface between the two pipe systems with its rim only, whereas the LCR-B liner is designed as a short liner in the down pipe or house sewer. The standard lateral repair length is 300 mm - the new LCR-B packer model allows a maximum repair length of 1300 mm. The LCR-B liner and hat material is suitable for steam curing and has high mechanical properties and very good sealing capabilities. In order to reduce the curing time, Trelleborg Pipe Seals is offering a steam generator (SteamGen V3). Behaviour in bends Depending on the actual host pipe run or on wrinkles formed in the installed liner: 45° for DN 100 main line 90° for DN 125 or larger main line Wall thickness of 2 to 3 mm Benefits

- Meets practical needs: Successful repairs with little equipment needs only, even in the presence of bends.

- Price advantage: Low investment cost, because you need to buy just the packers actually required.

- Practical: The low-weight mobile unit with low space requirements can be placed even in a small car.

- Flexibility: The job can be done with air push rods; no carriage needed.

- Accessibility: The LCR-B packers can be folded as required.

- No risk of fire: The resin system used for the liner system is self-extinguishing.

-

Method for the Sectional Renovation of Lateral Junctions and Pipes in the Main Sewer Line Main pipe: DN 130 to DN 600 Lateral pipe: DN 100, 125, 150 and 200 at 30° to 90° The DrainLCR-S system is used to repair and permanently seal main/lateral interfaces and connections up to 500 mm from the mainline down into the lateral. The system can use either an LCR-S hat profile or an LCR-S liner. The main-to-lateral interface in the main pipe is sealed only by the rim of the LCR-S hat profile, while the LCR-S liner in the main pipe is designed as a short liner. Benefits:

- Reliable to install: 1. Inversion is not possible until positive engagement of the pathfinder. 2. The signal will not sound until complete inversion.

- Technical advance: Only the inversion process allows pipe bends and offset joints to be relined.

- Meets practical needs: Successful repairs are possible with little equipment needs only, even in the presence of groundwater.

- Price advantage: Low investment cost, because you need to buy just the packers actually required.

- Practical: The low-weight mobile unit with low space requirements can be placed even in a small car.

- Flexible: It is also possible to use air push rods or a carriage.

- Accessibility: The LCR packers can be folded as required inside the manhole.

- User-friendly equipment: The LCR packers can be converted to other sizes as required.

-

Resin systems for full rehabilitation and sectional renovation of pipes and sewers. Trelleborg Pipe Seals manufactures high-quality resin systems for the rehabilitation of sewers and wastewater pipes. Three basic resin types are available:

- EpoxyResins for CIPP lining applications; and

- SilicateResins for lateral connection repairs and patches. Available in fast WOI, Winter and Summer.

Trelleborg Resin Systems

Two-component resin mixture made of component A (synthetic resin) and B (hardener) Trelleborg EPROPOX resins are used in the Trelleborg DrainLiner methods (CIPP liners) as well as in the Trelleborg DrainLCR methods. To be able to meet the varied needs of our installers, we developed a multitude of epoxy resin systems geared to specific applications. These systems stand out for their improved mechanical properties, e.g. flexural modulus, flexural stress, TG and reduction factor, which are considerably higher than those found in conventional resin systems. Thanks to their viscosity and surface tension, all EpoxyResin systems are extremely easy to handle, penetrate carrier materials quickly and provide very good mechanical properties and chemical strengths after final cure. Both filled and unfilled resin systems are available, depending on the particular application.Silicate Resin Systems

These resin systems are used especially for lateral connection and short repairs (DrainLCR and DrainPacker). They are easy to handle and quick to install and stand out for their good mechanical properties and chemical resistance after final cure. The patented two-component resin mixture is made up of the components B (resin) and A (hardener) at a mixing ratio of 2:1 (by volume). Benefits:- Cures at ambient temperature within about 1 to 3 hours (cure times can be controlled and adjusted)

- Excellent performance both at extremely high and at extremely low temperatures

- Very good resistance to acids and caustics (pH 1 - 13.5) after final cure

- High temperature resistance of short/CIPP liner after final cure

- No volatile organic compounds (styrene free)

- Excellent adhesion to many pipe materials like vitrified clay, plastic, steel etc. with a close frictional and positive fit to HDPE pipes

- Virtually no shrinkage (<0.6%)

- Can be used at a wide range of ambient temperatures

- Excellent performance both at extremely high and at extremely low temperatures

- Expected service life of more than 50 years as proven by 10,000-hour test

- The cured resin is self-extinguishing and can thus be used in critical areas such as airports and tunnels

- Tested by independent bodies (IKT - Gelsenkirchen, WRc UK)

- In compliance with international standards such as DIBt, ASTM, WIS and DIN EN

-

Prevents infiltration between Liner and Host Pipe. The Drain Liner End Seal utilizes the patented Slotted Band® to provide maximum sealing force with a minimum reduction in pipe diameter. This unique design captures the rubber and compresses it against the host pipe and new CIPP liner creating a permanent mechanical seal. The patented Slotted Band is constructed from a single piece of Stainless Steel (EN 1.4307) precisely rolled to match the diameter of the CIPP liner. The unique shape of the Slotted Band provides the maximum amount of strength and sealing force with the least possible thickness. The band is then expanded using a hydraulic expansion tool. As the band expands the integral latching mechanism progresses from slot to slot, positively locking on each one until the next one is reached. There is an audible click created by the spring/rubber interaction as the band is expanded into place. Benefits

- Manufactured from EPDM Rubber and Stainless Steel to withstand the harsh sanitary sewer environment.

- Complies with material property requirements of ASTM C923

- Quick and easy to install

- Eliminates Infiltration/Exfiltration between the Liner and Host Pipe

my account | Talk to the experts 1800 028 584