Why downtime is killing contractors

Why downtime is killing contractor margins and why high-reliability service partners are becoming a competitive advantage

Author – Mark Quealy – Managing Director SECA

Downtime is one of the most expensive and least visible risks in wastewater infrastructure operations today.

Every hour a crew is parked instead of productive erodes margins, disrupts schedules, and damages trust with stakeholders.

But the root cause isn’t just equipment failure.

It’s the system around the equipment: Slow repairs, limited support, unavailable parts, untrained crews, inconsistent suppliers, and reactive decision-making.

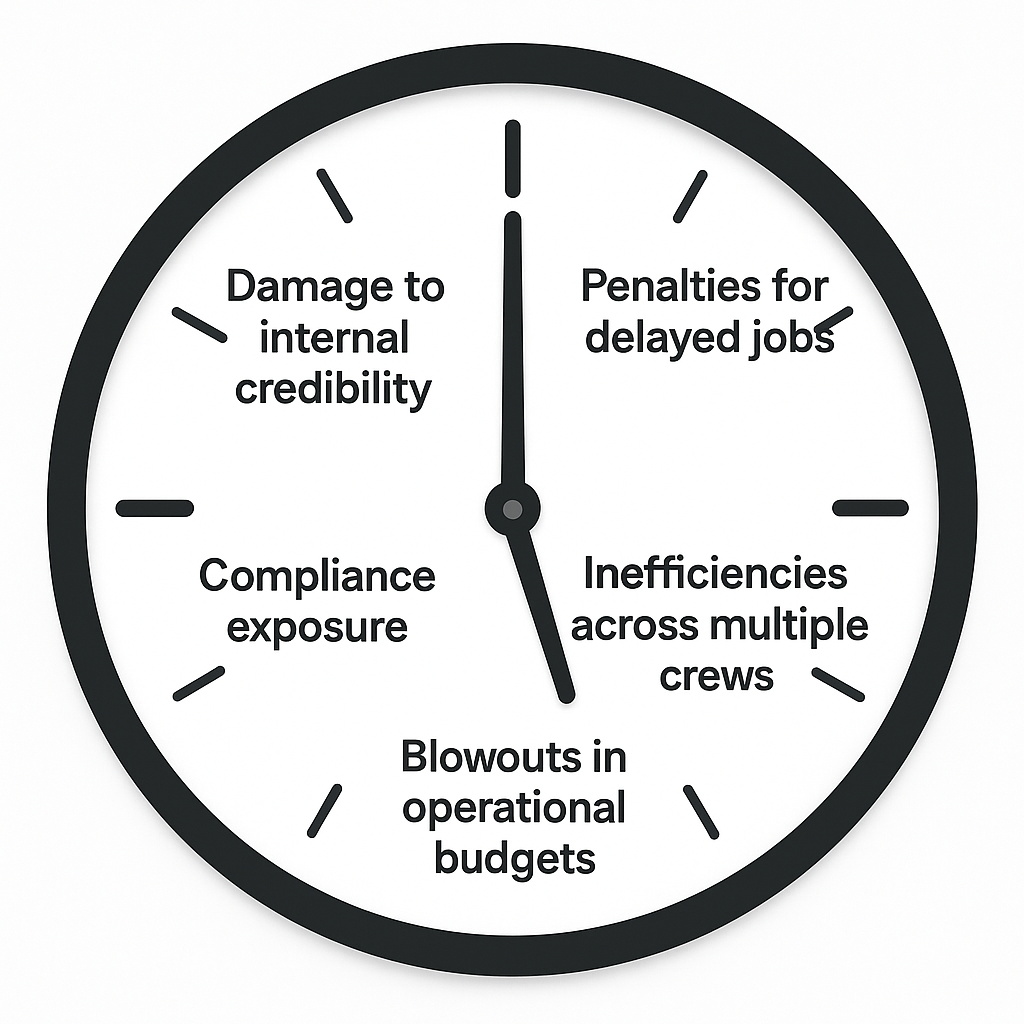

The true cost of downtime is no longer measured in hours lost it’s measured in:

- Penalties for delayed jobs

- Inefficiencies across multiple crews

- Blowouts in operational budgets

- Compliance exposure

- Damage to internal credibility

Why downtime hits contractors the hardest

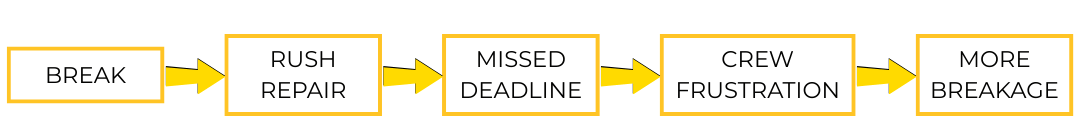

A broken camera or jetter stops more than one job it stops an entire crew.

When gear fails mid-project, the ripple effect is immediate:

- Crews stand idle

- Deadlines slip

- Supervisors scramble for workarounds

- Clients become frustrated

- Margins shrink as labour costs climb while output drops

This creates immediate revenue pain and multi crew disruption that impacts reporting, timelines, and internal KPIs.

Supplier delays compound the problem

Contractors routinely deal with slow parts dispatch, long servicing queues, and generic suppliers who don’t understand civil workflows.

This creates several issues making it harder for you to deliver. Things like:

- Inconsistent equipment across crews

- More training time

- More user error

- Higher rework rates

- Extended downtime during tenders or large projects

Managing multiple suppliers with incompatible service levels introduces unnecessary operational complexity.

Staff turnover increases downtime risk

With crews changing regularly, gear misuse becomes a hidden cost. Without proper training and support, even the best equipment fails earlier than it should.

This creates a cycle of:

Compliance and reporting pressure magnifies failures

There is constant scrutiny from councils, utilities and corporate leadership. Unplanned downtime puts these relationships and future tenders at risk.

How high-reliability service partners change the game

Organisations performing best share one thing, they partner with suppliers who treat uptime as a measurable outcome not an accident.

Having the right partnerships in place means; faster turnaround, quality repairs manageable turnaround times. We believe the supplier relationship should be strategic not transactional.

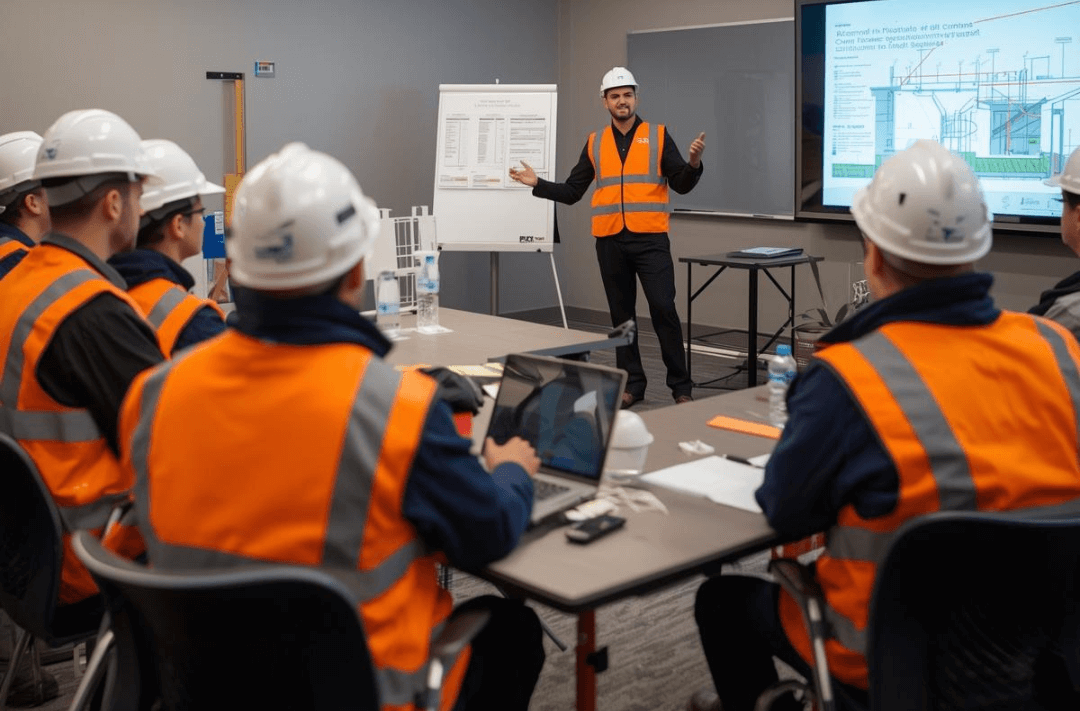

Training reduces user error and improves adoption

Untrained teams are one of the biggest hidden drivers of downtime. The right partner can also help ensure your team are using their equipment correctly to ensure longevity and ongoing compliance. Knowing your team are trained ensures consistent workflows across all crews reducing rework and improving margins.

Downtime isn’t just a cost it’s a competitive disadvantage

Reliable gear and support mean faster job completion, fewer delays, better tender performance, and higher client trust.

High reliability is no longer a premium feature it’s an operational strategy.

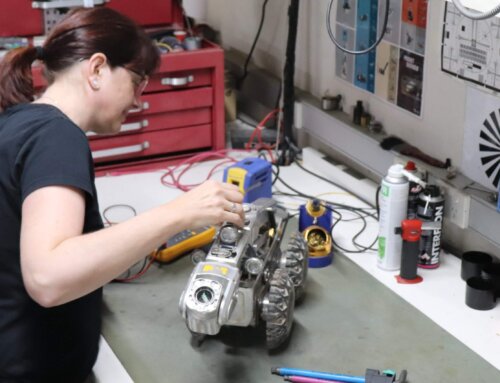

How SECA Helps Reduce Downtime for you and your team

- Fast turnaround servicing and local spare parts

- Highly trained technicians who understand civil & sewer operations

- Council-ready documentation and compliance support

- Training programs built for multi-crew rollout and adoption

- Long-term partnership not just transactional sales

Reliability Is a Strategic Decision

Whether you’re a contractor delivering major civil projects or an authority responsible for public assets, downtime is no longer an operational hiccup it’s a structural threat to performance.

Organisations that invest in reliable service ecosystems are outperforming those that operate reactively.

Because reliability builds:

- Trust

- Predictability

- Efficiency

- Competitive advantage