Unveiling the Secrets of Buried Pipes: How Modern Tools Work Together for Detailed Insights

Unveiling the Secrets of Buried Pipes: How Modern Tools Work Together for Detailed Insights

Posted by Kristel Hudson on -21-May-2024 13:55:10 Find me on: LinkedIn

Ever wonder how engineers and asset owners manage to get such detailed insights into buried pipes? The process might seem complex, but thanks to advanced technology, it’s a lot more straightforward than you might think.

Here’s how the magic happens:

The Role of the Profiler and Rovion’s Pan/Tilt Camera

🔦 Step One: Illumination

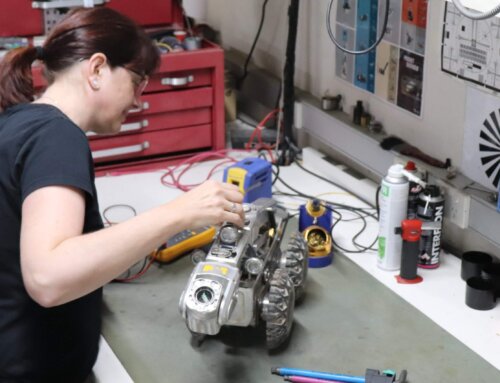

The process starts with a profiler, a specialised tool that projects a ring of light onto the interior walls of the pipe. This ring of light is meticulously captured by Rovion’s pan/tilt camera. The camera’s ability to move and adjust angles ensures that every part of the pipe is thoroughly scanned and recorded. This initial step is crucial as it sets the stage for the detailed analysis that follows.

WinCan’s Laser Module: Extracting and Modeling

📹 Step Two: Extraction and 3D Modeling

Once the camera captures the illuminated pipe interior, WinCan’s laser module steps in. This sophisticated piece of equipment extracts the light profile from the video footage. Using this data, it constructs a highly accurate 3D model of the pipe’s interior. Unlike traditional CCTV inspections that provide a flat, 2D view, this 3D model offers a comprehensive and precise representation of the pipe.

The Benefits of a 3D Pipe Model

📐 Step Three: Measurement and Analysis

The 3D model generated by WinCan’s laser module is not just a visual aid. It provides precise measurements of various pipe attributes, such as anomalies, pipe geometry, and defects. These measurements are crucial for several reasons:

- Planning Repairs: The detailed model helps engineers plan repairs with high precision. Knowing the exact dimensions and locations of defects allows for more efficient and targeted interventions.

- Accurate Defect Identification: Traditional CCTV inspections might miss subtle but significant defects. The 3D model, however, leaves little to chance, ensuring that even minor issues are detected and documented.

- Monitoring Erosion and Corrosion: Over time, pipes can suffer from erosion or corrosion. The 3D model helps in monitoring these processes by providing a clear picture of the pipe’s condition at different points in time.

- Verification and Lifecycle Assessment: These models can be used alongside CCTV data to verify proper installation of new pipes. They also help in determining the remaining useful life of existing pipes, facilitating better maintenance planning, and budgeting.

Why is This Important?

The ability to create a 3D model of a pipe’s interior revolutionises how we approach pipe inspection and maintenance. These models not only improve the accuracy and efficiency of identifying and repairing defects but also play a critical role in proactive maintenance strategies. By understanding the exact state of buried pipes, municipalities and companies can avoid catastrophic failures and extend the life of their infrastructure.

In summary, the collaboration of profilers, advanced cameras, and laser modules provides a detailed and invaluable insight into the condition of buried pipes. This synergy of tools transforms a traditionally challenging task into a precise and manageable process, ensuring the integrity and longevity of our essential underground infrastructure.

Ready to transform your pipe inspection and maintenance process? Discover the precision and reliability of modern pipe inspection technology today. Contact us to learn more about how our advanced tools can give you unparalleled insights into your buried pipes.[/vc_column_text][/vc_column][/vc_row]