Unveiling the Depths of Innovation in Sewer Maintenance with Sewer Robotics

Pioneers in UHP Water Jet Cutting

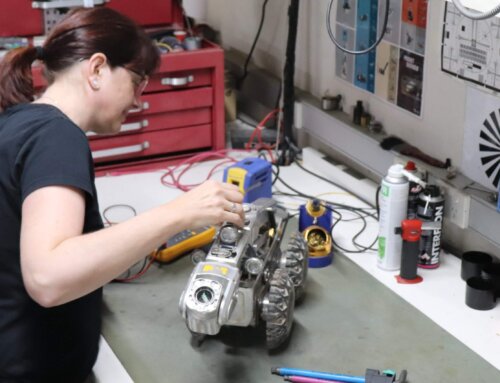

Sewer Robotics proudly holds the title of being the first company to introduce Ultra High-Pressure (UHP) water jet cutting through a specialised crawler. This cutting-edge technology proved to be a game-changer, allowing their customers to remove solid obstructions and deposits efficiently. Over the past 15 years, Sewer Robotics has honed its UHP water jet cutting experience, reflected in the precision and reliability of their directional cutting robots.

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”8205″ img_size=”500×250″ onclick=”zoom”][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][vc_single_image image=”8207″ img_size=”300×450″ onclick=”zoom”][/vc_column][vc_column width=”3/4″][vc_column_text]The Sewer Robotics Advantage

Sewer Robotics stands as the proud manufacturer of a modular, single-system solution encompassing a multifunctional crawler and various job-specific modules. This all-in-one system proves highly effective and cost-efficient, catering to tasks such as underground pipe inspection, cleaning, cutting, and rehabilitation.

This robust system tackles a spectrum of challenges, from removing root intrusions and cutting protruding taps to reinstating lateral connections. It excels in installing spot repair systems and eliminating heavy grease, over-poured concrete, as well as years of calcium and scale build-up in pipes ranging from 150 to 1000mm (6-40 inches) underground.[/vc_column_text][vc_column_text]

Water Jet Cutting Mastery

Sewer Robotics specialises in water jet cutting with its WJ250 water jet module. Crafted from durable stainless steel, this module exhibits the knowledge of over 15 years of UHP water jet cutting expertise. Capable of delivering a powerful 3000bar (43,600psi) water blast, the WJ250 operates seamlessly in pipelines of varying diameters up to 1000mm (40 inches).

Reinstatement cutting becomes a breeze with Sewer Robotics’ water hydraulic cutter motor, swiftly slicing through materials like cast iron, concrete, and CIPP liner material while leaving a smooth cut. The simplicity in design and minimal parts ensure ease of service at low costs, showcasing the company’s commitment to efficiency and reliability.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]Intelligent Cleaning with C70 Video Nozzle

Sewer Robotics introduces the C70 Video Nozzle, a testament to their commitment to innovation. This camera nozzle captures HD video while jet cleaning underground pipelines, seamlessly integrating into cleaning workflows. With pressure-switched recording and automatic cloud synchronisation, valuable intelligence is gathered at minimal cost and effort.

Upon completion of cleaning tasks, users can download the video for immediate pipe status visualisation. Alternatively, all videos can be uploaded to Sewer Analytics, complete with date, time, and GPS location, streamlining data management for comprehensive analysis.

[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”8210″ img_size=”full” onclick=”zoom”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_single_image image=”8213″ img_size=”500×300″][/vc_column][vc_column width=”1/2″][vc_column_text]The Future of Sewer Maintenance

As Sewer Robotics continues to evolve, it reinforces its position as an industry leader in sewer maintenance technology. Their commitment to precision, reliability, and innovation ensures that municipalities and service providers worldwide can tackle sewer challenges efficiently and cost-effectively.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]SECA: Exclusive Distributor for Sewer Robotics in Australia and New Zealand

Taking this transformative technology to the Southern Hemisphere, we proudly announce our exclusive partnership with Sewer Robotics as the sole distributor of this cutting-edge system in Australia and New Zealand.

For more information about Sewer Robotics, call our national number on

1800 028 584 or contact your nearest SECA branch.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”8212″ img_size=”full” onclick=”zoom”][/vc_column][/vc_row]