Trelleborg DrainPacker: The Smarter Way to Repair Pipes — No Digging Required

As Australian infrastructure continues to age, the need for efficient, non-invasive pipe repair solutions has never been more urgent. That’s where Trelleborg’s DrainPacker system comes in — a reliable, trenchless pipe rehabilitation method designed to restore damaged sections of sewer and stormwater pipelines without excavation.

Whether you’re a plumber, contractor, or council asset manager, this system makes sectional pipe repair simple, cost-effective, and compliant with Australian regulations.

What Is the DrainPacker System?

The Trelleborg DrainPacker is a short-liner method used to repair localised damage inside gravity pipelines — typically for pipe diameters ranging from DN 100 to DN 600 (with options up to DN 1200). It uses an inflatable packer and a glass-fibre mat saturated with silicate resin to create a structural, watertight lining inside the pipe.

Benefits for the Australian Market

- Trenchless technology – No need to dig up roads, driveways or landscaped areas

- Fast curing – Silicate resins cure within 1–3 hours at ambient Australian temperatures, even in wet or partially flowing pipes

- Durable – Independently tested to last over 50 years, with many installations rated for up to 100 years

- Environmentally safer – Resins are styrene-free, low VOC, and suitable for potable water systems in accordance with AS/NZS standards

- MRWA Compliant – Systems and materials are recognised by the Major Roads Water Authority (MRWA) in Victoria and compliant with WSAA codes

Ideal Applications

- Cracked or corroded pipes

- Joint displacement or leaking connections

- Root intrusion points

- Patch repairs for stormwater and sewer networks

- Closing unused laterals

- Under roads, buildings, carparks or landscaped areas

How It Works

- Prepare the Pipe – Use high-pressure water jetting and CCTV inspection to locate and clean the area needing repair.

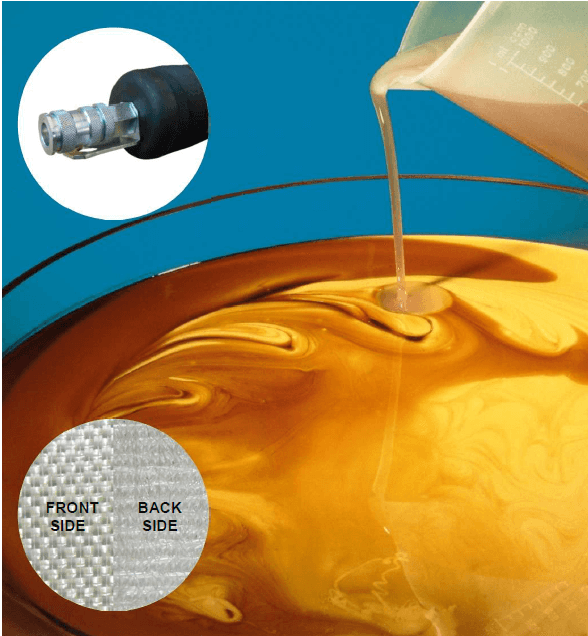

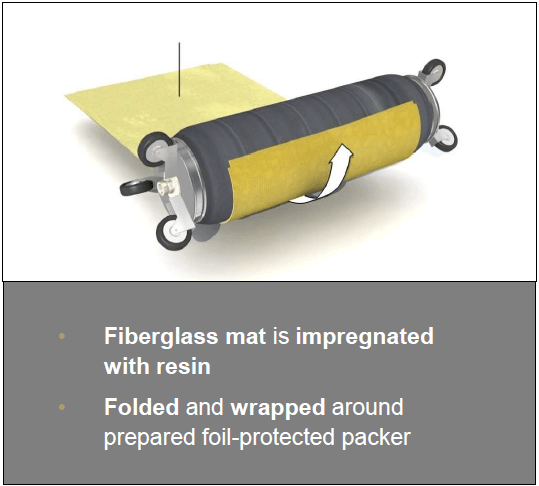

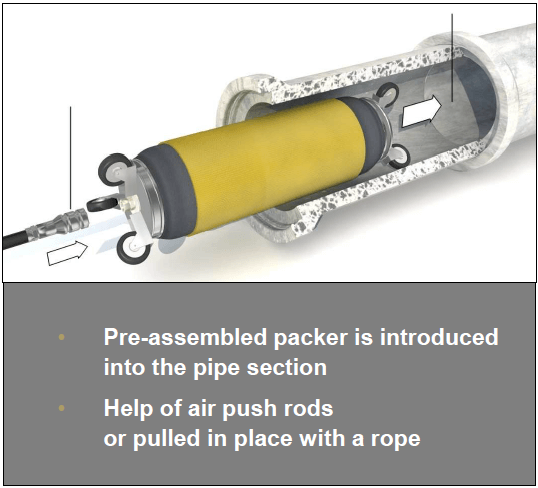

- Fill the Mat – A glass-fibre mat is saturated with silicate resin and wrapped around an inflatable packer.

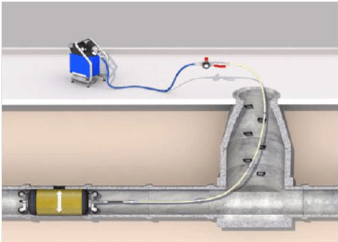

- Position & Inflate – The packer is positioned at the defect site and inflated to press the mat against the pipe wall.

- Cure & Remove – Once cured (usually in 60–180 minutes), the packer is deflated and removed, leaving a smooth, sealed internal liner.

Certified Quality

- Tested to ASTM F1216, DIN EN 13566-4, and local standards

- MRWA-endorsed products and installation practices

- Fire-retardant and suitable for high-traffic areas like airports and tunnels

- Designed for use in PVC, vitrified clay, cast iron, concrete, GRP and HDPE pipelines

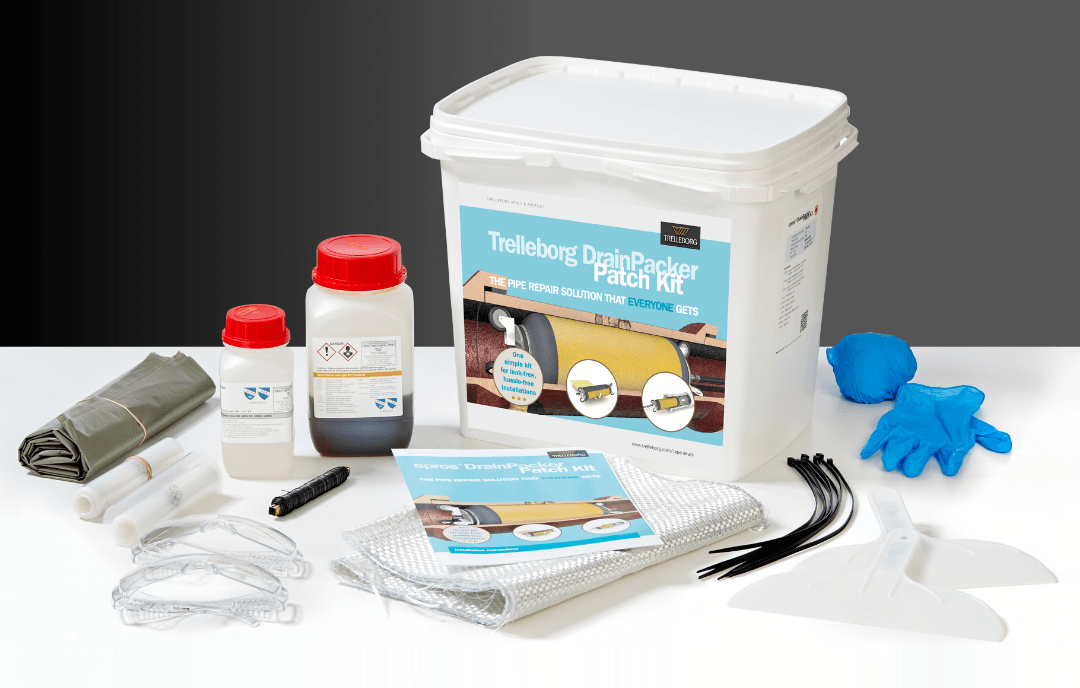

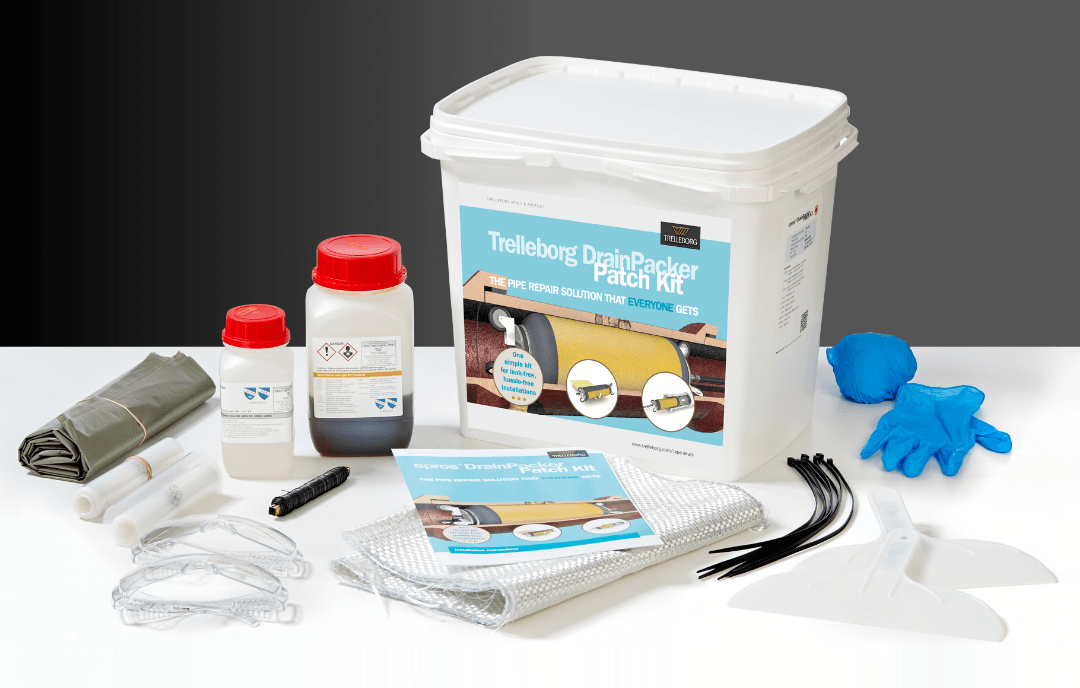

What’s in the Kit?

- Range of inflatable short, long, flex and lateral packers

- Silicate resin – designed for fast cure and underwater application

- CRF+ glass-fibre mats in 1050g/m² or 1400g/m² thickness

- Push rods, air compressor, pressure gauges, and CCTV tools required

- Full training and certification available in Australia

Why It’s a Smarter Choice

Trelleborg’s DrainPacker system is a game-changer for trenchless pipe repair in Australia. It reduces downtime, eliminates the need for excavation, and provides long-lasting structural results. It’s perfect for councils, utilities, contractors and plumbers looking to modernise their approach with fewer environmental and community impacts.