RootX & GreaseX: Proven Solutions for Pipeline Maintenance

Maintaining healthy sewer and stormwater pipelines is one of the biggest challenges for councils, contractors, and property managers. Two of the most common issues are tree root intrusion and grease build-up, both of which can cause blockages, environmental damage, and costly emergency repairs.

At SECA, we provide practical solutions with RootX® and GreaseX® – industry-proven products designed to prevent blockages, extend the life of assets, and keep your networks flowing.

Tree Root Control with RootX

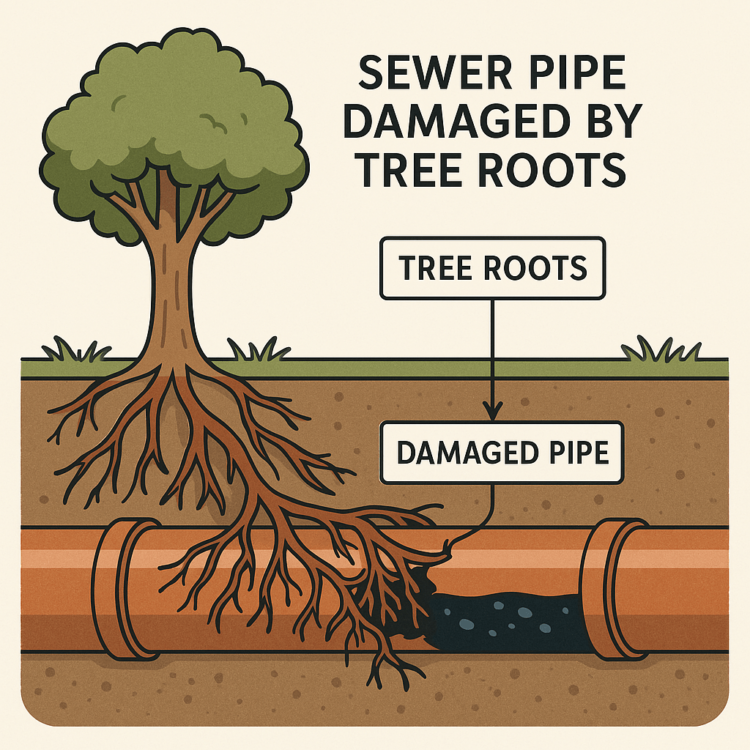

Why Roots Target Sewer Pipes

Tree roots are naturally drawn to moisture and nutrients, making small cracks and joints in sewer lines the perfect entry point. Once inside, roots expand and quickly cause:

- Reduced flow and partial blockages

- Pipe damage or collapse if untreated

- Frequent, expensive maintenance

- Traditional cutting or jetting only offers a short-term fix – roots will simply grow back.

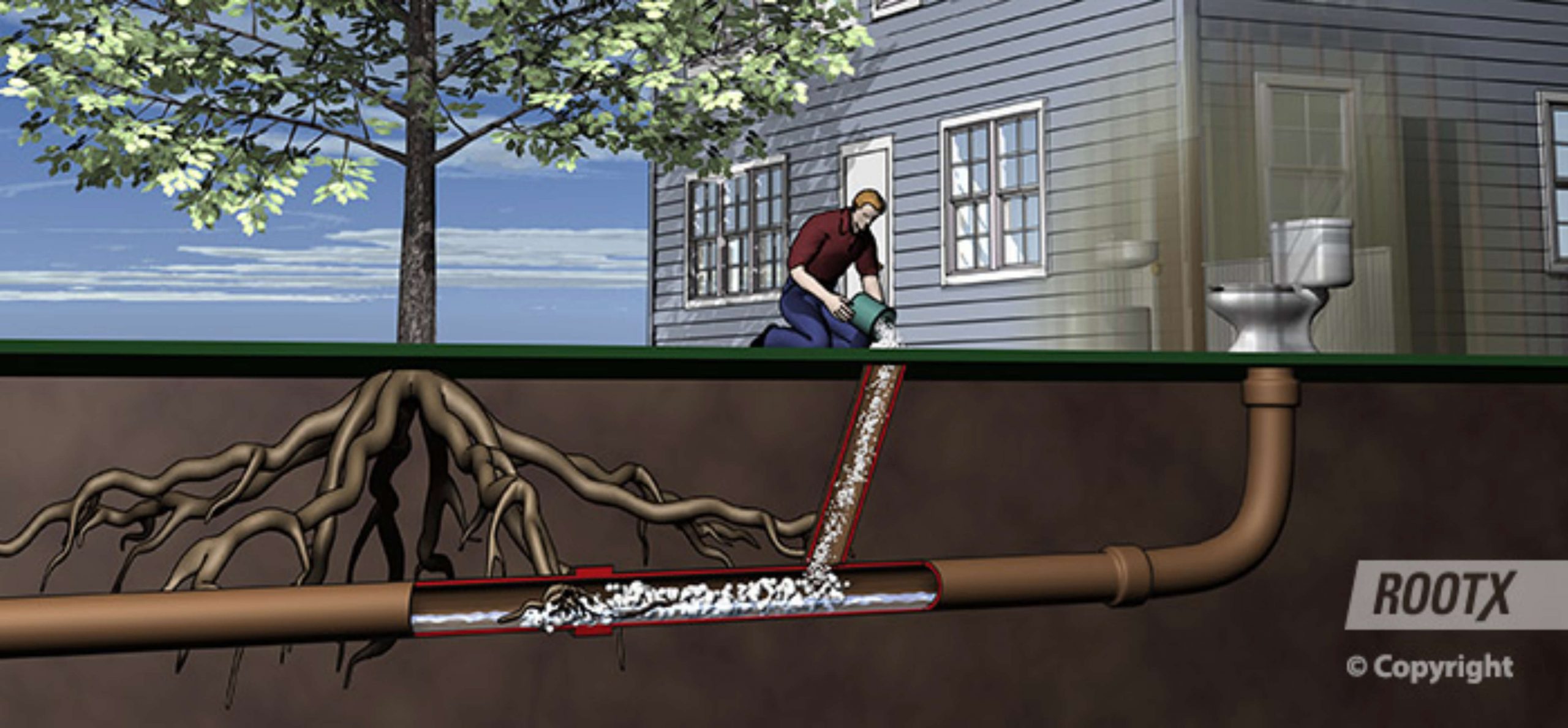

How RootX Works

RootX® is a foaming herbicide developed specifically for sewer applications:

- Expands to fill the entire diameter of the pipe, coating walls thoroughly

- Kills roots on contact and prevents regrowth for up to 12 months

- Safe for surrounding trees, plants, and the environment when applied correctly

- Extends the life of sewer infrastructure and reduces emergency call-outs

Grease Build-Up Control with GreaseX

The Impact of Grease in Pipelines

Fats, oils, and grease (FOG) are among the most common causes of sewer blockages. As FOG cools, it solidifies inside pipes, restricting flow and creating odours. Over time, this leads to:

- Slow drains and overflows

- Environmental hazards

- Expensive, reactive clean-ups

How GreaseX Works

GreaseX® is a biological grease treatment designed to digest FOG and organic build-up

- Uses natural bacteria and enzymes to safely break down grease deposits

- Prevents blockages, corrosion, and foul odours

- Environmentally friendly and suitable for both small and large networks

- Ideal for preventative maintenance in residential, commercial, and municipal systems

The Power of RootX & GreaseX Together

While RootX and GreaseX address different problems, they work best as part of a preventative pipeline maintenance program. Using both solutions helps:

- Reduce long-term operating costs

- Extend the lifespan of critical infrastructure

- Prevent costly overflows and environmental fines

- Keep communities and businesses running without disruption

RootX FAQ’s

Question |

Answer |

| What is RootX? | A professional foaming root-control treatment for sewer and drain networks that kills intrusive roots and helps prevent regrowth. |

| How does it work? | The two-part formula foams on contact, carrying actives to the pipe crown and laterals. It coats roots and pipe walls, killing root tissue inside the pipe and inhibiting regrowth. |

| Where can it be used? | Gravity sewer mains, laterals, maintenance holes, and stormwater lines where root intrusion is present (subject to local authority approval). Not for potable water lines. |

| Do we need to clean the line first? | Yes—restore flow first (jet/rod or mechanical cut). Then apply RootX to kill remaining root stubs and inhibit regrowth. Avoid further cutting for several weeks after treatment. |

| How is it applied? | Introduced via downstream manhole or cleanout using a foaming nozzle or application kit. Follow the dose rate for pipe diameter/length and maintain contact time. |

| How quickly does it work? | Foam goes to work immediately; dead root material typically decays and washes away over weeks with normal flows. |

| How long does protection last? | Programs typically retreat annually or as inspection data indicates (often 6–12 months efficacy depending on species, soil, and network conditions). |

| Will it harm the tree? | It targets roots inside the pipe. When used as directed, it does not systemically kill the tree. Always follow label directions and local regulations. |

| Is it safe for pipes? | Compatible with common pipe materials (PVC, concrete, vitrified clay, cast iron, HDPE) when used as directed. |

| Is CCTV allowed after treatment? | Yes—CCTV is commonly used to verify results. Avoid mechanical cutting shortly after application to allow the chemistry to work. |

| Does it affect biological treatment? | When applied correctly in the collection system, impact on downstream treatment processes is minimal. Observe specified dosages and volumes. |

| What about environmental compliance? | Use only in closed sanitary/storm systems as permitted. Prevent discharge to waterways. Follow SDS, label, and local authority requirements. |

| Can it be used in wet weather? | Yes, but heavy inflow/infiltration can reduce contact time and foam stability. Plan applications for best hydraulic conditions. |

| How do we size the dose? | By pipe diameter and section length (and whether mains or laterals). Use the dosing chart on the label or application guide. |

| How soon can the line return to service? | Immediately—no shutdown required. Normal flows help carry foam to the crown and laterals. |

| What PPE is required? | Standard chemical-handling PPE: gloves, eye protection, suitable clothing/respirator as per SDS, plus confined-space and traffic-control procedures. |

| Storage & shelf life? | Store sealed in a cool, dry place away from oxidisers/ignition sources. Use within the labelled shelf-life; keep components dry and separate until use. |

| Packaging options? | Supplied as a two-part kit in sizes matched to common pipe diameters and run lengths (mains and lateral packs). |

| How do we verify results? | Post-treatment CCTV (typically 6–8 weeks after application) and ongoing asset inspections to set the retreatment cycle. |

| Can homeowners use RootX? | It’s a professional product. For private laterals, use approved contractors trained in safe handling and dosing. |

| Is training available? | Yes—SECA can provide application training, dosing guidance, and integration into your proactive maintenance program. |

Why Choose SECA?

For over 55 years, SECA has partnered with councils, contractors, and utilities to deliver the future in pipeline technology. We don't just supply products – we provide the training, support, and expertise to help you get the best results.

With RootX and GreaseX, you can be confident in choosing proven, safe, and effective solutions backed by SECA's experience.

Ready to Protect Your Pipelines?

Speak to our team today about how RootX and GreaseX can reduce blockages and protect your network.