Top 10 Push Camera Features Every Inspector Needs: A Complete Buyer’s Guide for 2025

The evolution of inspection technology has transformed how professionals conduct detailed examinations of pipes, ducts, and confined spaces. At the heart of this transformation lies the push camera – a sophisticated tool that has become indispensable for modern inspection work.

In today’s demanding inspection environment, the difference between a successful project and a frustrated client often comes down to equipment reliability and image quality. Push cameras have evolved from simple viewing tools to comprehensive inspection systems, integrating advanced imaging technology, data management, and reporting capabilities.

Understanding Push Camera Technology

The complexity of modern inspection work requires a deep understanding of how push camera systems function and interact with various environments.

Basic Components

The effectiveness of a push camera system relies on three core elements working in harmony:

1. Camera Head:

- Advanced imaging sensors calibrated for pipe environments

- Impact-resistant housing designed for frequent collisions

- Specialised lens systems with scratch-resistant coatings

- Integrated lighting arrays positioned for maximum visibility

- Optional sensors for temperature and incline measurement

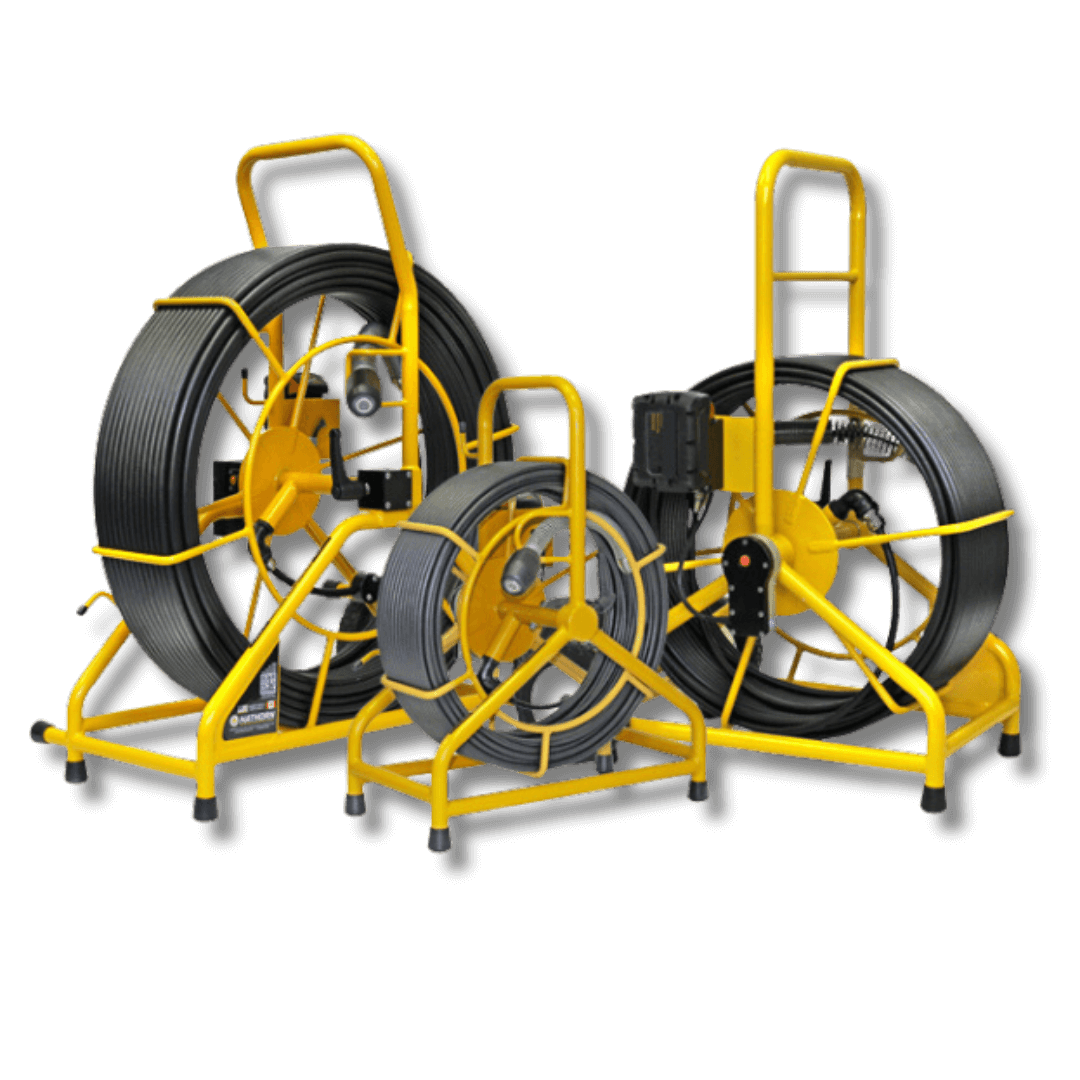

2. Cable Assembly:

- Multi-layer construction for durability and flexibility

- Reinforced core to prevent stretching under tension

- Water-blocking layers to protect internal electronics

- Kevlar strengthening members for push capability

- Distance markers for accurate depth measurement

- Specialised jacketing for chemical resistance

3. Control Unit:

- High-brightness display with anti-glare coating

- Intuitive interface design for gloved operation

- Multiple recording and playback options

- Data annotation and report generation

- Battery management system with status monitoring

Essential Features Breakdown

1. Image Quality and Resolution

Modern push cameras must balance image quality with practical usability. Here’s a detailed breakdown of crucial imaging features:

1.1 Resolution Considerations:

a. HD Resolution (1080p minimum):

- Enables clear identification of cracks as small as 0.5mm

- Provides adequate detail for most inspection requirements

- Balances file size with image quality

b. 4K Capabilities:

- Offers superior detail for specialised inspections

- Particularly valuable for detailed condition assessments

- Requires more storage and processing power

1.2 Image Enhancement Features:

- Digital image stabilisation

- Automatic focus adjustment

- Dynamic range optimisation

- Colour correction for different pipe materials

- Defogging algorithms for humid conditions

2. Cable Design and Flexibility

The cable is the literal backbone of any push camera system. Its design directly impacts your ability to complete inspections efficiently:

2.1 Advanced Cable Technologies:

Core Construction:

- Hybrid fibre/steel design for optimal push capability

- Variable stiffness sections for different pipe configurations

- Integrated strain relief at connection points

- Torque-balanced design to prevent twisting

2.2 Lighting Patterns:

- Forward-focused for long pipe runs

- Wide-angle for large-diameter inspection

- Side illumination for crack detection

- Regulated output for consistent recording

3. Recording and Storage Capabilities

Modern inspection work requires comprehensive documentation:

3.1 Recording Features:

- Multiple format support (H.264, H.265)

- Variable bitrate recording

- Time-lapse capabilities

- Voice annotation support

- Automatic report generation

3.2 Storage Solutions:

- Dual SD card slots for redundancy

- USB 3.0 high-speed transfer

- Cloud integration options

- Automatic backup systems

- Project-based file organisation

4. Advanced Control Systems

Modern push cameras incorporate sophisticated control systems:

4.1 Control Features:

- Touch-screen interface with glove support

- Customisable quick-access buttons

- Gesture controls for standard functions

- Remote operation capabilities

- Multi-language support

4.2 Reporting Capabilities:

- Automated defect recognition

- Measurement tools

- Location mapping

- Condition assessment templates

- Client report generation

5. Display Screen Quality

The display unit is your window into the inspection world, making its quality crucial for accurate assessments:

Display Technologies:

5.1 IPS Panel Benefits:

- Wide viewing angles (178 degrees)

- True color reproduction

- Minimal color shift

- Better contrast ratios

5.2 Screen Specifications:

- Minimum 7-inch diagonal display

- 1000+ nit brightness for sunlight visibility

- Anti-glare coating with fingerprint resistance

- Toughened glass protection

- Multi-touch capability with wet/glove operation

Display Features Table:

| Feature | Standard | Premium |

| Size | 7-inch | 10-inch+ |

| Resolution | 1280×720 | 1920×1080 |

| Brightness | 800 nits | 1500+ nits |

| Touch Points | 5-point | 10-point |

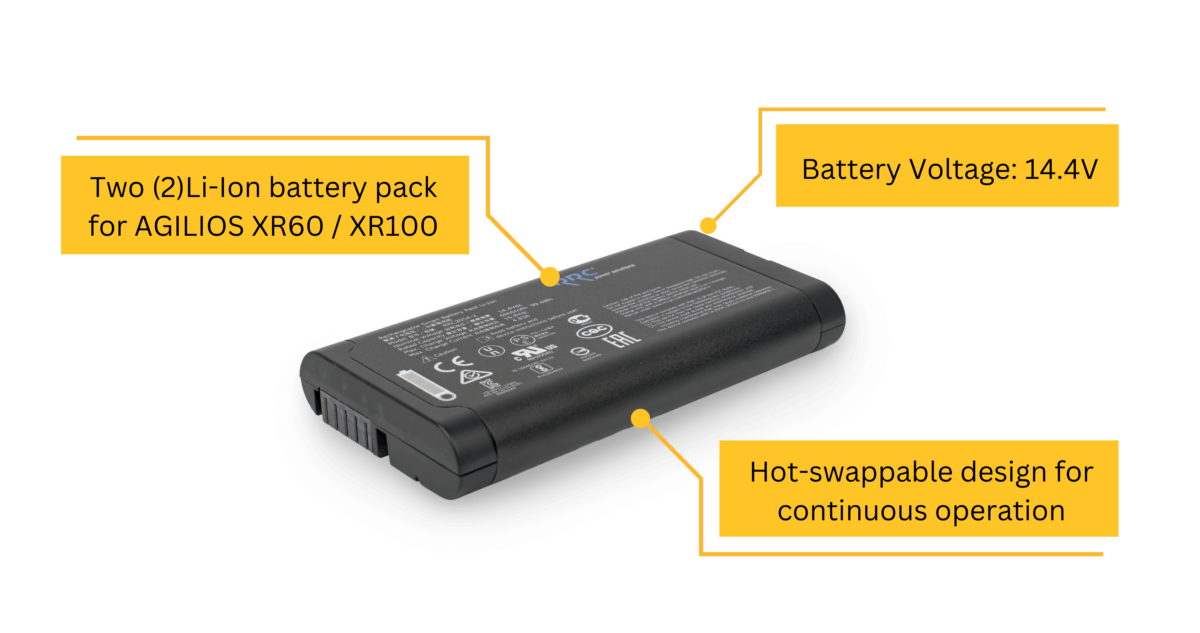

6. Battery Life and Power Management

Professional inspections demand reliable power systems:

6.1 Battery Technology:

- Lithium-ion cells with protection circuits

- Hot-swappable design for continuous operation

- Smart charging with temperature monitoring

- Battery health indicators

- Multiple charging options

6.2 Power Management Features:

- Intelligent sleep modes

- Priority system shutdown

- Power consumption monitoring

- Emergency backup power

- Quick-charge capability (0-80% in 45 minutes)

Runtime Specifications:

- 8+ hours of continuous operation

- 12+ hours standby time

- 3-4 hour charge time

- 1000+ charge cycle lifetime

7. Connectivity Features

Modern inspection systems must integrate seamlessly with other technologies:

7.1 Wireless Capabilities:

- Dual-band WiFi (2.4GHz/5GHz)

- Bluetooth 5.0 for accessories

- GPS location tracking

- Mobile app integration

- Remote control capabilities

7.2 Data Management:

- Real-time streaming to devices

- Cloud storage integration

- Automatic backup systems

- Multiple export formats

- Report generation tools

- 8+ hours of continuous operation

- 12+ hours standby time

- 3-4 hour charge time

- 1000+ charge cycle lifetime

8. Camera Head Design

The camera head’s design directly impacts inspection capabilities:

8.1 Advanced Features:

- Auto-levelling technology

- 360-degree rotation

- Pan and tilt functions

- Shock absorption system

- Replaceable lens covers

8.2 Specialised Capabilities:

- Laser measurement tools

- Side-scan capability

- Multiple camera angles

- Pressure sensors

- Temperature monitoring

Camera Head Options:

- Standard (23mm-25mm)

- Mini (16mm-18mm)

- Micro (12mm-14mm)

- Custom sizes for specific applications

9. Additional Tools and Attachments

Enhance inspection capabilities with specialised accessories:

Essential Attachments:

9.1 Centring Devices:

- Multiple size options

- Quick-release mechanisms

- Adjustable roller systems

- Protective brush designs

9.2 Measurement Tools:

- Laser measurement modules

- Calibrated reference markers

- Crack width gauges

- Slope measurement tools

9.3 Specialised Equipment:

- Lateral launch systems

- Pipe cleaning attachments

- Sample collection tools

- Retrieval devices

Compatibility Features:

- Universal mounting systems

- Tool-free attachment changes

- Secure locking mechanisms

- Modular design for upgrades

Maintenance and Longevity

Protecting your investment requires systematic care:

1. Daily Maintenance:

- Cable cleaning and inspection

- Connection check and cleaning

- Battery maintenance

- Storage procedures

- System diagnostics

2. Preventive Maintenance Schedule:

- Weekly deep cleaning

- Monthly calibration checks

- Quarterly software updates

- Annual professional servicing

- Cable wear monitoring

Industry-Specific Applications

Different sectors have unique requirements that influence feature selection:

1. Plumbing Sector:

- Emphasis on compact camera heads

- Need for excellent low-light performance

- Chemical resistance for cleaning products

- Quick-connect fittings for multiple tools

2. HVAC Applications:

- Wide-angle viewing capabilities

- Enhanced lighting for dark spaces

- Flexible cable for tight bends

- Temperature-resistant components

3. Industrial Inspections:

- Robust construction for harsh environments

- Extended cable lengths

- Advanced measurement tools

- Chemical and temperature resistance

Selecting the right push camera system requires careful consideration of these essential features. Focus on the elements that align with your inspection needs and working conditions. Remember that the best system is one that consistently delivers reliable results in your particular application.

Frequently Asked Questions

Q: What is the ideal cable length for residential inspections?

A: A 30-50 meter cable typically suffices for residential work. However, consider that:

- Most residential jobs require only 20-30 meters

- Extra length provides flexibility for unexpected situations

- Longer cables can be harder to manage and transport

- Consider having multiple length options available

Q: How often should push camera equipment be calibrated?

A: Professional calibration is recommended:

- Full professional calibration annually

- Self-checks monthly

- After any significant impact or damage

- When measurement accuracy seems off

- Before critical inspection projects

Q: Can push cameras work in pressurised pipes?

A: Standard push cameras are designed for non-pressurized systems. However:

- Special-rated cameras exist for low-pressure systems

- Maximum pressure ratings vary by manufacturer

- Always verify pressure ratings before use

- Consider pressure release before inspection

Technical Considerations

Q: What IP rating is recommended for sewer inspections?

A: For sewer inspections:

- Minimum IP68 rating required

- IP68 preferred for extended submersion

- Consider chemical resistance ratings

- Verify gasket and seal integrity regularly

Q: How long do push camera batteries typically last?

A: Battery life varies by usage, but expect:

- 8+ hours of continuous use

- 10-12 hours with intermittent use

- 3-4 hours recharge time

- Battery life degrades 15-20% annually

Maintenance Questions

Q: What’s the best way to clean a push camera system?

A: Proper cleaning involves:

- Wipe down cable during retrieval

- Use manufacturer-approved cleaning solutions

- Clean camera head lens after each use

- Dry thoroughly before storage

- Regular connector cleaning

Q: How should I store my push camera?

A: Optimal storage practices include:

- Keep in climate-controlled environment

- Coil cable properly using manufacturer guidelines

- Store control unit separately when possible

- Use protective covers on all connections

- Avoid direct sunlight

Performance and Troubleshooting

Q: What affects image quality most in pipe inspections?

A: Key factors include:

- Lighting conditions

- Camera cleanliness

- Cable signal quality

- Display screen settings

- Environmental conditions

Q: How can I prevent cable twisting?

A: Minimize twisting by:

- Using proper insertion techniques

- Maintaining appropriate push speed

- Utilising guide wheels when available

- Regular cable maintenance

- Proper storage practices

Investment and Value

Q: What’s the expected lifespan of a professional push camera system?

A: With proper maintenance:

- 5-7 years for professional systems

- 3-5 years for entry-level systems

- Camera heads: 2-4 years

- Cables: 3-5 years depending on usage

- Control units: 5+ years

Q: Which features offer the best value for money?

A: Priority features include:

- High-quality imaging system

- Durable cable construction

- Reliable lighting system

- Good water resistance

- Strong warranty coverage

Take your inspection work to the next level with professional-grade push camera systems from SECA. Our team of technical specialists understands the unique challenges inspection professionals face and can help you select the perfect equipment for your specific needs. Whether you’re upgrading existing equipment or investing in your first push camera system, we’ll guide you through every feature, specification, and option to ensure you make an informed decision. Don’t let inferior equipment hold back your inspection capabilities – contact SECA today for expert advice, competitive pricing, and ongoing support that keeps you operating at peak efficiency. Visit www.seca.com.au to explore our comprehensive range of inspection solutions, or contact our technical team for personalised recommendations that align with your professional requirements. Transform your inspection capabilities with SECA’s expertise and industry-leading equipment solutions.