Sewer Camera Buying Guide

Plumbing inspection technology has revolutionised how we approach pipe maintenance and repairs. Making an informed investment in a sewer camera requires careful consideration of multiple factors. Whether you’re a professional plumber, municipal worker, or facility manager, this comprehensive guide will help you navigate the complex world of pipe inspection equipment.

Modern pipe inspection has transformed from basic flashlight-and-mirror techniques to sophisticated camera systems that provide detailed insights into underground infrastructure. Today’s sewer cameras combine advanced imaging capabilities with robust construction to provide reliable underground diagnostics. Understanding the available options and features is, such as the right drain inspection camera, crucial for making an informed purchasing decision that aligns with your needs.

Understanding Sewer Camera Types

The sewer inspection industry offers diverse specialised equipment to meet varying inspection needs. From basic push cameras to sophisticated crawler systems, each type serves specific purposes and offers unique advantages. Understanding these differences is crucial for making an informed investment that aligns with your operational requirements.

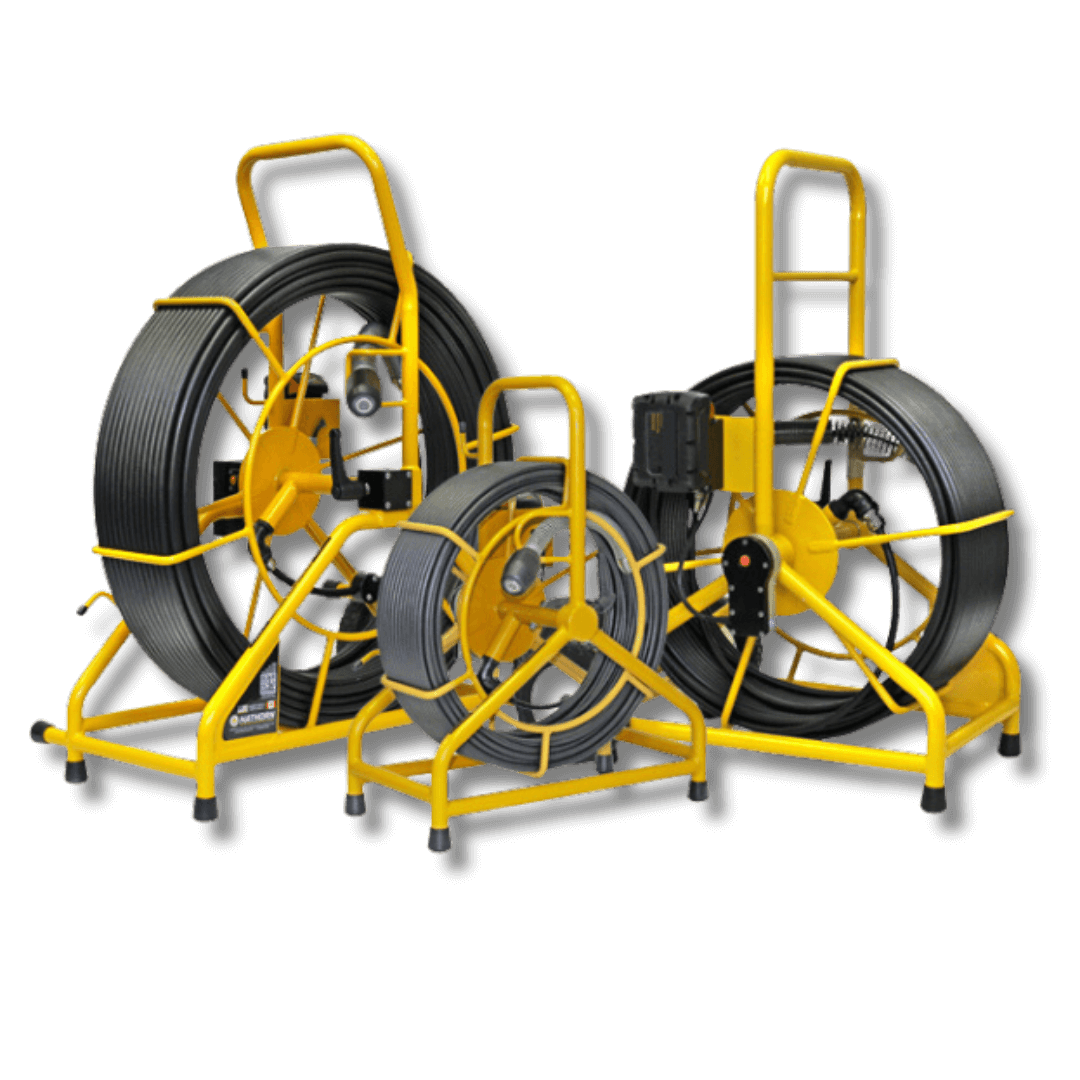

Push Rod & Portable Inspection Systems

For plumbing professionals and service providers, selecting the right inspection equipment can make all the difference in efficiency, accuracy, and cost. Push rod cameras and portable inspection systems represent two of the most versatile and accessible solutions on the market—particularly for residential and small commercial applications.

Push rod cameras are the foundation of many inspection setups. Designed for simplicity and reliability, they are ideal for inspecting smaller pipes and tight spaces. These manually operated systems offer:

- Compatibility with pipes 1 to 4 inches in diameter

- Typical reach of 100 to 200 feet

- Straightforward, manual controls

- A budget-friendly option for essential inspections

These features make push rod cameras particularly useful for diagnosing common residential issues like drain blockages, root intrusions, or broken pipes.

Complementing these are portable inspection systems, which cater to professionals who need mobility and rapid deployment. These battery-powered units are engineered for ease of transport and quick setup, making them invaluable for time-sensitive or multi-site jobs. Key advantages include:

- Lightweight, compact design for easy transport

- Battery-powered operation for use in remote or hard-to-access locations

- Ideal for quick, preliminary inspections

- Reduced setup time for greater efficiency

Together, push rod and portable systems deliver a highly practical inspection toolkit. Whether you’re diagnosing a blocked residential line or performing a quick check in a commercial facility, these solutions offer the performance and convenience needed to get the job done efficiently.

Crawlers/Mainline Cameras

For larger-scale operations, crawler systems represent the pinnacle of pipe inspection technology. These sophisticated units offer advanced capabilities essential for professional applications:

- Remote-controlled operation

- Suitable for pipes 6 inches and larger

- Extended reach up to 1000+ feet

- Pan, tilt, and zoom functionality

| Feature | Basic Crawler | Advanced Crawler |

| Camera Resolution | 480p | 1080p or higher |

| Control Range | 500 ft | 1000+ ft |

| Lighting | Fixed LED | Adjustable LED array |

| Recording | Basic video | HD video + photos |

Essential Features to Consider

The effectiveness of your pipe inspection operations heavily depends on the quality and capabilities of your equipment. Modern systems combine multiple technologies to deliver comprehensive inspection solutions.

Camera Quality and Resolution

The quality of your inspection camera directly impacts diagnosis accuracy and reporting capabilities. Modern inspection systems should offer:

- 4K HD cameras for unparalleled clarity and detail

- Minimum 1080p resolution for standard inspections

- Advanced LED lighting arrays with adjustable intensity

- Built-in image stabilisation for clearer footage

Professional-grade sewer cameras now include features like:

- Auto-focus capabilities for quick inspections

- Side-scanning capabilities for complete pipe analysis

- High dynamic range (HDR) for challenging lighting conditions

Cable and Probe Specifications

Your cable system needs to withstand constant use in harsh conditions. Key considerations include:

- Fiberglass push rods with a minimum 10mm diameter for stability

- Kevlar reinforcement for increased tensile strength

- Highly flexible cable core with a crush resistance

- Waterproof connectors rated to IP68 standard

The ideal cable should feature the following:

- Clear distance markers at 1-metre intervals

- Wear-resistant outer coating

- Self-levelling camera heads

- Quick-connect terminations for easy maintenance

Control Systems and Interface

Modern control interfaces combine user-friendly operation with comprehensive functionality. The evolution of digital technology has revolutionised how operators interact with their equipment:

- Touch-screen displays with anti-glare coating

- Minimum 10-inch screen size for comfortable viewing

- Customisable inspection reporting templates

- Cloud integration for real-time data sharing

Advanced systems now offer:

- Voice annotation capabilities

- Built-in report generation

- WiFi connectivity for remote viewing

- Multiple operator profiles for team use

Cost Analysis and ROI

Understanding the financial implications of your investment is crucial for business planning. The market offers solutions across various price points to match different operational needs:

| System Type | Price Range (AUD) | Typical Applications |

| Entry-Level Push Cameras | $7,500-20,000 | Residential, Small Commercial |

| Mid-Range Systems | $20,000-55,000 | Commercial, Light Industrial |

| Professional Crawlers | $55,000-140,000 | Municipal, Large Industrial |

| Complete Truck Systems | $140,000+ | Major Infrastructure |

When calculating ROI, consider:

- Average inspection revenue ($300-800 per job)

- Typical weekly usage (15-20 hours)

- Maintenance costs (approximately 5% of purchase price annually)

- Equipment lifespan (5-7 years with proper maintenance)

Professional systems typically pay for themselves within 18-24 months of regular use, making them a sound investment for established businesses.

Environmental and Technical Requirements

The demanding nature of pipe inspection work requires equipment that can withstand various challenging conditions. Understanding these requirements ensures your investment can handle the rigors of daily use.

Waterproofing and Durability

Essential protection features include:

- IP68 rating for full submersion

- Corrosion-resistant materials

- Impact-resistant housing

- Temperature tolerance

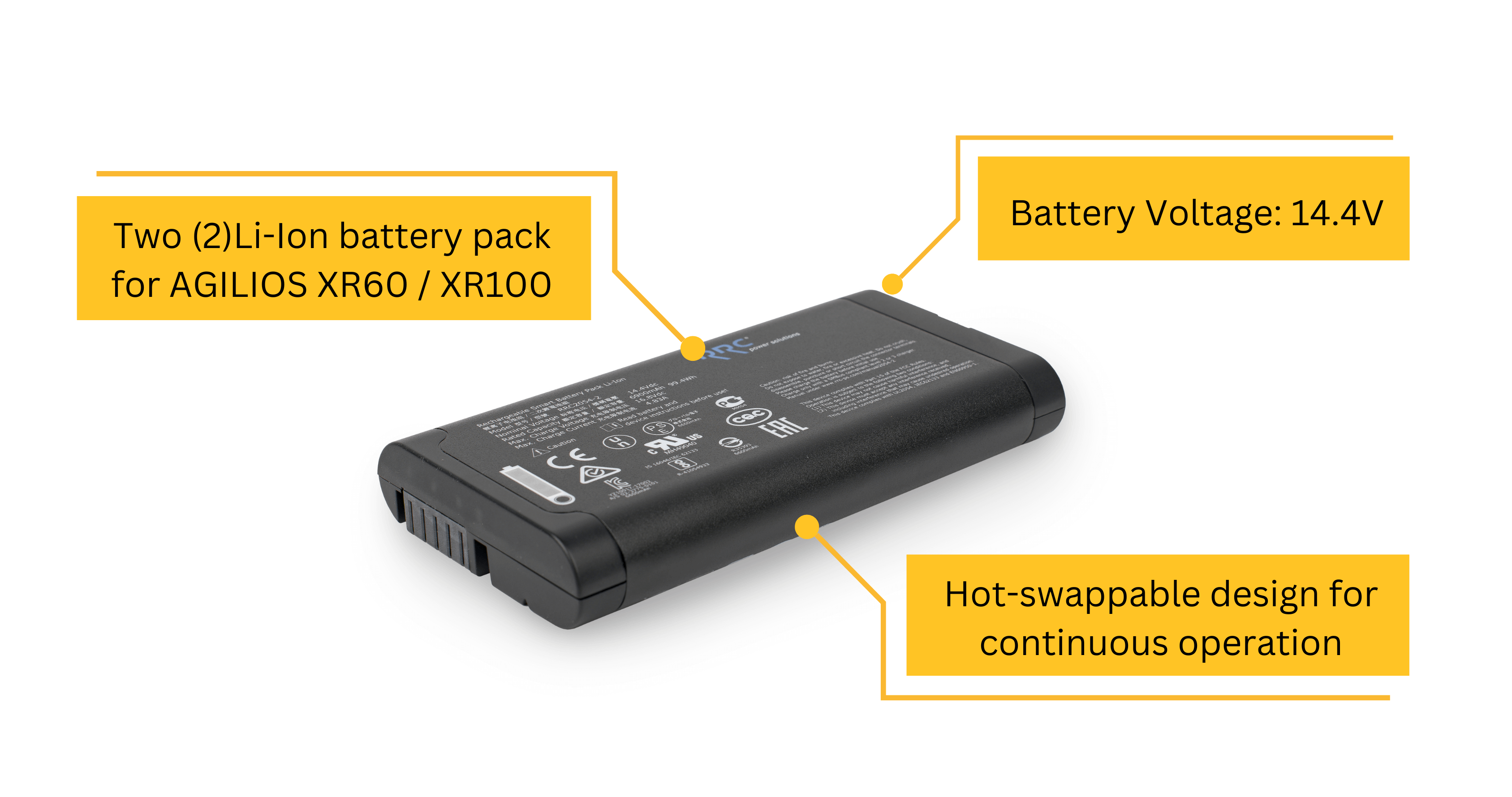

Power and Battery Life

Modern inspection systems must balance performance with operational longevity. Key operational considerations include:

- Minimum 4-hour battery life

- Quick-charge capabilities

- Backup power options

- Power management features

Choosing the Right System for Your Needs

Selecting the appropriate inspection system requires thoroughly evaluating your business requirements and future growth plans. Consider these critical factors when selecting equipment:

- Primary application types

- Typical pipe diameters

- Required inspection distances

- Budget constraints

- Growth projections

Frequently Asked Questions

Q: What is the typical lifespan of a sewer camera? A: Professional systems typically last 5-7 years with proper maintenance.

Q: How much training is required? A: Basic systems require 1-2 training days, while advanced crawlers may need 3-5 days.

Q: Can cameras work in fully submerged conditions? A: Professional-grade cameras with proper IP ratings can operate fully submerged.

Q: What maintenance is required? A: Regular cleaning, cable inspection, and annual professional servicing are recommended.

Choosing the Right Sewer Camera System: A Smart Investment for Your Business

The selection of an appropriate sewer camera system represents a crucial business decision that impacts operational efficiency and service quality. Consider your needs, growth plans, and budget constraints when making this critical investment. Professional consultation can help ensure you choose equipment that will serve your needs effectively now and in the future.

Ready to invest in professional pipe inspection equipment? SECA‘s expert team is here to guide you through the selection process. Contact us today and visit us at www.seca.com.au for tailored recommendations that match your business needs.