Revolutionising Pipeline Inspections with AI and WinCan Web

Revolutionising Pipeline Inspections with AI and WinCan Web

Posted by Kristel Hudson on 17 January 2024 17:01:00 Find me on: LinkedIn

The way we inspect pipelines is evolving rapidly, and artificial intelligence (AI) is playing a huge role in making the process smarter, faster, and more reliable. With advancements in technology, AI-assisted coding is transforming sewer and stormwater inspections, improving accuracy and cutting down time spent on manual tasks.

Recently, Hugh O’Sullivan, WinCan BDM for SECA, conducted an in-depth training session with our team, showcasing how WinCan Web AI is revolutionising the pipeline inspection industry. Hugh, who holds a Bachelor of Environmental Science (BEnvSc), has over 15 years of experience in the industry. He has trained extensively in Switzerland and regularly attends training sessions directly with WinCan, ensuring that SECA remains at the forefront of pipeline inspection technology.

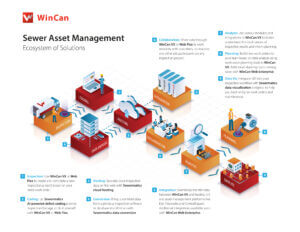

One of the biggest game-changers in this space is WinCan Web, a cloud-based platform that makes it easy to process, analyse, and share pipeline inspection data. This blog explores how WinCan Web’s AI capabilities are changing the industry and why it stands out compared to traditional methods and alternative AI solutions.

From Manual Coding to AI-Powered Efficiency

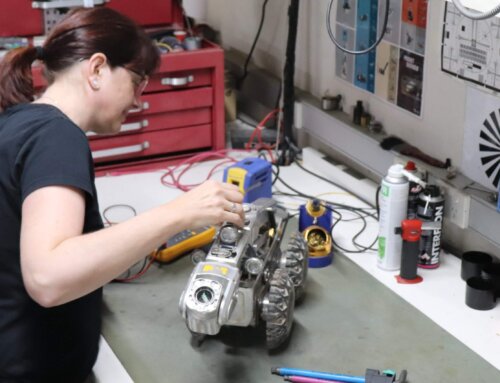

Traditionally, pipeline inspections involved a technician operating a CCTV crawler or push camera, stopping at defects, and manually coding observations. In some cases, the footage would then be sent to an office for another specialist to code, leading to double-handling and longer turnaround times.

AI is shaking up this process by allowing operators to focus purely on capturing high-quality video footage. The AI then scans the footage and automatically identifies defects with an accuracy rate of 70-90%, reducing the need for extensive manual input. However, human oversight remains essential for quality assurance and compliance with industry standards.

How WinCan Web AI Works

- Upload Footage: Inspection videos are uploaded to WinCan Web.

- AI Analysis: The AI scans the footage to identify structural and service defects, such as cracks, root intrusions, displaced joints, and infiltration/exfiltration.

- Defect Classification: Observations are categorised and scored based on severity using standard grading systems.

- Human QA Review: Operators or engineers review AI-generated observations, making edits if necessary.

- Report Generation & Sharing: The final reports can be easily shared via WinCan Web, eliminating excessive file transfers and manual report compilation.

Why WinCan Web AI Stands Out

✅ Saves Time – Reduces coding time by up to 66%, allowing quicker report generation.

✅ Reliable & Consistent – AI applies standardised coding (WSAA and NZPIM), reducing human error.

✅ Cloud-Based Access – All data is stored in WinCan Web, making it accessible from anywhere.

✅ Integrated Workflow – Eliminates the need for transferring files between multiple platforms.

✅ Scalable & Cost-Effective – Charged per metre, so you only pay for what you use.

WinCan Web AI vs Alternative AI Solutions: Key Differences

Some contractors might compare WinCan Web AI with other AI-based inspection solutions. However, Wincan Web AI offers significant advantages:

| Feature | WinCan Web AI | Other AI Solutions |

| Fully Integrated Workflow | ✅ Yes – AI processing & reporting all in one platform | ❌ No – Requires manual file transfers |

| Live Filtering & Analysis | ✅ Yes – Users can filter and sort observations | ❌ No – Only provides PDF reports |

| Editable AI Reports | ✅ Yes – Users can edit observations in WinCan Web | ❌ No – Reports are static PDFs |

| Cloud-Based Sharing | ✅ Yes – Instant sharing via web links | ❌ No – Requires separate downloads |

With WinCan Web, everything from inspections to coding and reporting happens within one platform, avoiding the inefficiencies of multiple software transfers.

Final Thoughts

AI-powered pipeline inspections are here, and WinCan Web is leading the way. By automating defect identification and simplifying workflows, WinCan Web allows operators and engineers to focus on what matters most – making informed decisions and delivering high-quality reports.

If you’re looking for a smarter, more efficient way to handle pipeline inspections, WinCan Web AI is the future.

Want to see it in action? Contact us today to start your free trial and experience the next generation of pipeline inspection technology!

WinCan’s AI is already reshaping how water utilities and contractors manage inspection data. When paired with a cloud-based inspection management solution, teams can start getting familiar with AI technology at all levels.

Contact us today to schedule a demo and see how AI can optimise your operations.