Get Your Gear Ready for the Christmas Shutdown: A Cleaning Guide for Contractors & Plumbers

Posted by Felix Chau on 13-December-2025

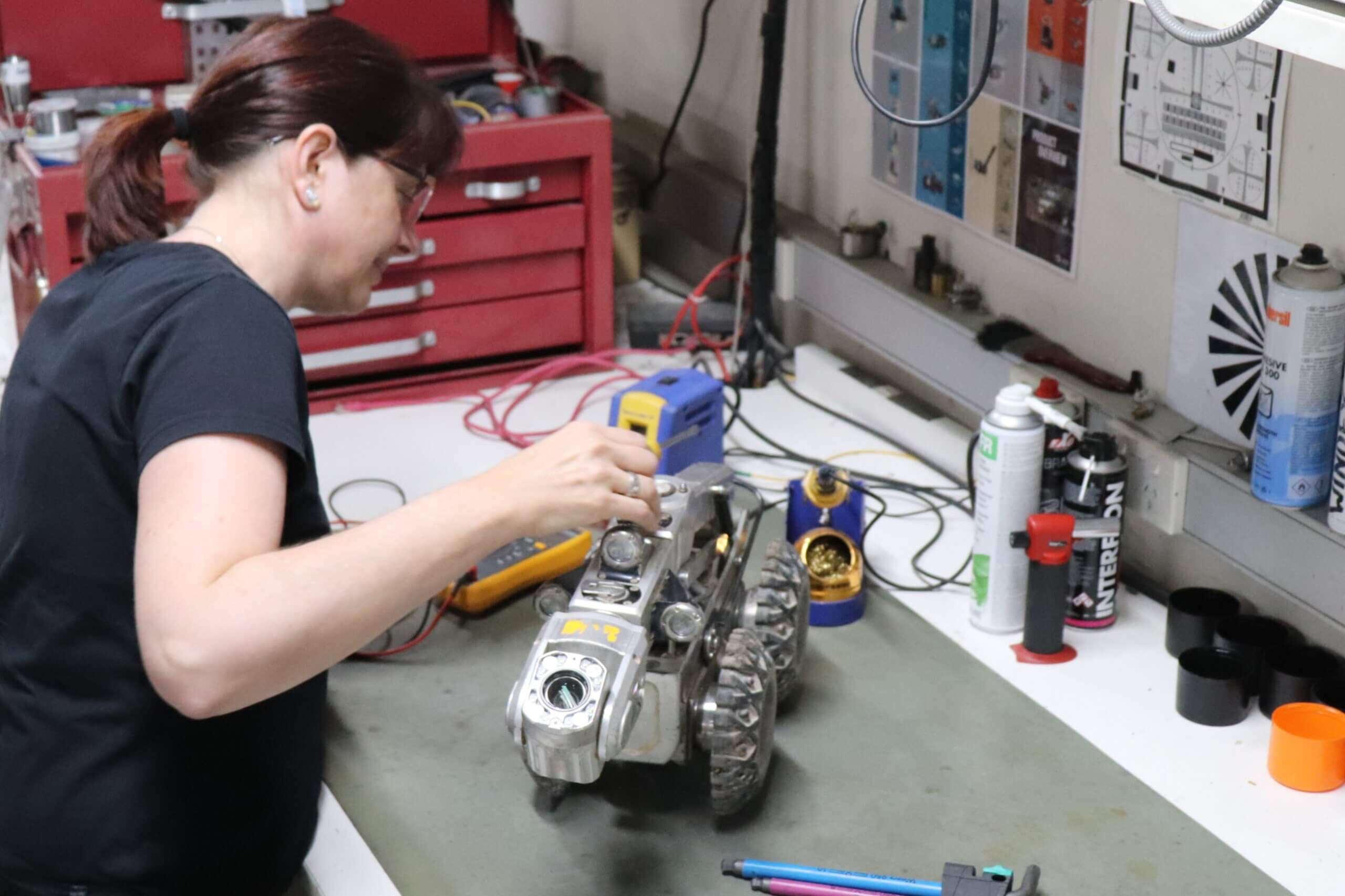

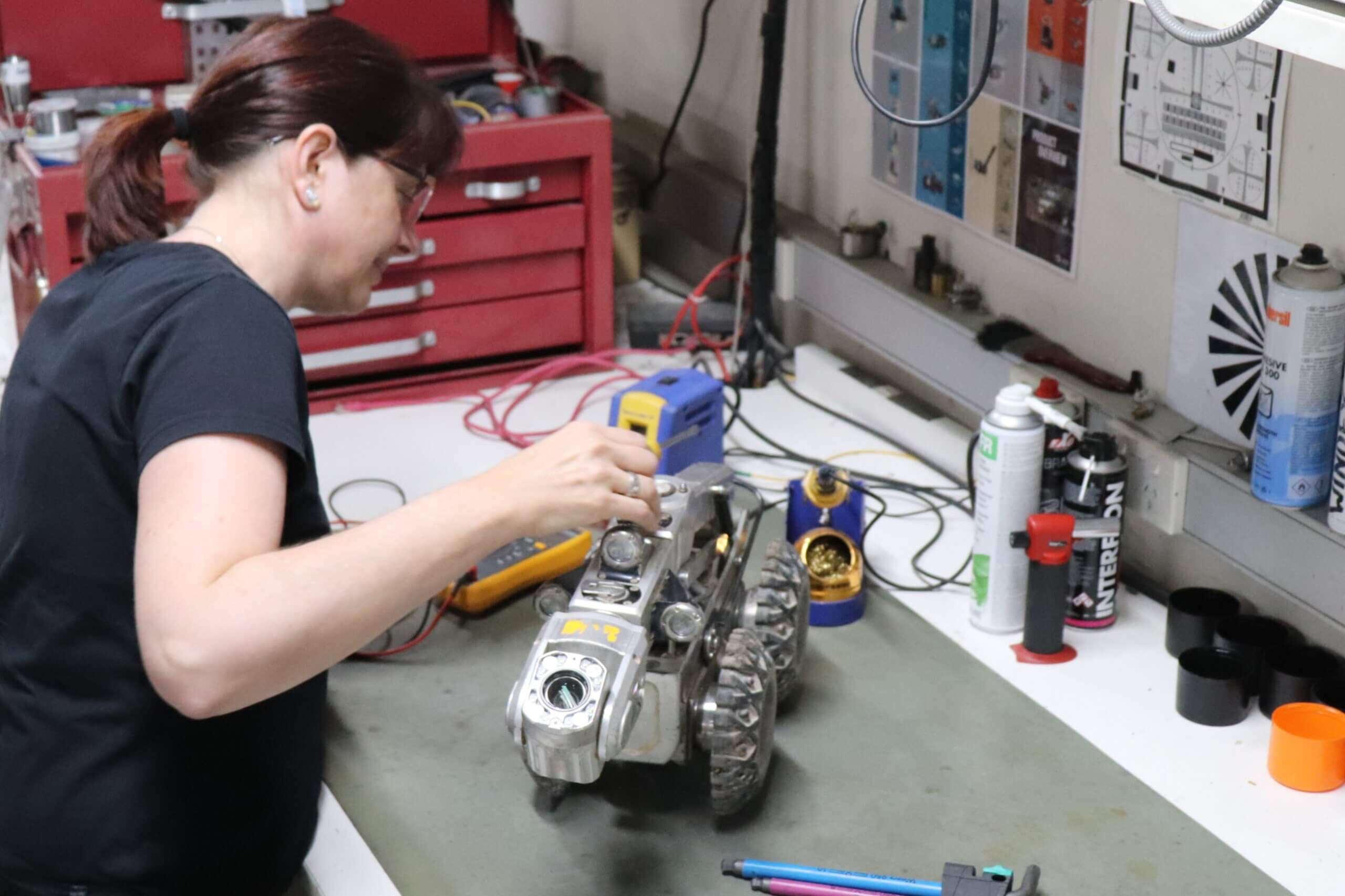

As the year winds down and crews prepare for the Christmas shutdown, it’s the perfect moment for contractors and plumbers to give their sewer inspection gear a proper end-of-year clean. Whether you’re managing multiple teams or working through busy pre-holiday callouts, a bit of preventative maintenance now will save you time, money and stress in January.

A clean, well-checked crawler or camera system comes back online faster – without unexpected faults or downtime delaying your return to work.

This guide brings together SECA’s recommended cleaning and care steps to help you finish the year well prepared.

Why Cleaning Before Shutdown Matters

Leaving equipment dirty or damp over the holiday break can result in:

- Corrosion on exposed or moving parts

- Deterioration of seals, connectors and cables

- Image quality issues from dirty lenses or worn components

- Mechanical strain from grit trapped inside wheel hubs or joints

- Costly repairs when work restarts

Keeping your gear maintained protects your investment and avoids job delays in the new year.

Step-by-Step: Pre-Holiday Cleaning Essentials

1. Start With a Low-Pressure Rinse

Wash away heavy debris from crawlers, cameras and cables using a gentle rinse. High pressure can force water past seals and into housings.

2. Scrub Wheels, Tracks & Body Components

Use a soft brush to remove sediment from wheels, tracks, axles and undercarriage areas as these parts take the biggest beating on worksites.

3. Clean the Camera Head Safely

Pat relies on a crisp image, so treat the camera head with care:

- Use a microfiber cloth

- Use only approved lens cleaning solutions

- Avoid alcohol-based cleaners

- Check for scratches or lens window damage

4. Wipe Down & Inspect Cables

As cables are reeled in, wipe them clean and inspect for:

- Cuts or nicks

- Stretched or compressed sections

- Kinks or crushed points

- Connector wear or corrosion

5. Dry All Components Thoroughly

Moisture left over the break causes corrosion and electrical faults. Air dry components or use a clean, lint-free cloth.

6. Store Correctly

- Keep equipment in a cool, dry, dust-free area

- Release tension on cables

- Use caps and protective cases

- Avoid stacking heavy items on sensitive equipment

Additional Maintenance Tips

Check Moving Parts & Lubricate

Before storing equipment, you should take a minute to:

- Rotate wheels and track components to confirm smooth movement

- Check crawler joints, arms and pivot points

- Apply manufacturer-approved lubricant sparingly to moving parts

- Inspect screws, mounts and brackets for looseness

A quick once-over now helps prevent seized components in January.

Perform an Integrity Test Before Shutdown

For both contractors and plumbers, running a quick integrity check ensures the system is healthy before going into storage:

Integrity Test Checklist

- Power up all components to check for startup or communication faults

- Run the crawler or camera head a short distance to check wheel motion, track alignment and overall drive performance

- Test the lighting system to confirm LEDs are functioning

- Check the video feed for clarity, distortion or flicker

- Verify telemetry (tilt, speed, distance counter) is accurate

- Confirm all cables and connectors seat correctly without wobble or intermittent signal

Why this matters

Any minor issue found now can be logged, planned and booked for early-January servicing – avoiding the new-year backlog.

Ready to keep your CCTV equipment performing at its best?

Download our free Pre-Holiday Crawler Cleaning Checklist and make sure your crawler cameras, equipment and cables are protected over the break. If you need help servicing your equipment or booking a pre-Christmas integrity test, our SECA team is here to support you. Get in touch today and keep your fleet inspection-ready for 2026.