Essential Guide to Sewer Inspection and Maintenance for Asset Owners

Getting the Jump on Sewer Inspection and Maintenance

Before delving into the world of underground sewer assets, it’s common for people to have little to no understanding of council sewer systems and their crucial role. Proactive asset management extends asset life, reduces community impact, cuts emergency repair costs, and protects the environment. This guide provides essential information about sewer assets, potential issues, and maintenance processes to help asset owners stay ahead in maintaining their sewer systems.

The Importance of Sewer Maintenance

Maintaining sewer assets offers numerous benefits. It removes bacteria, biohazards, and chemicals from wastewater, promotes a healthy environment, and acts as a first defence line during natural disasters like floods. Sewer systems, transporting water from its source to a treatment plant or disposal site, consist of stormwater and sanitary sewers and components such as laterals, sewer mains, force mains, pump stations, basins, treatment plants, outfalls, and maintenance holes.

Stormwater sewers handle rainwater, runoff, and drainage, typically discharging untreated into local water bodies. Sanitary sewers transport household greywater and blackwater to wastewater plants for treatment before re-entering the environment. Using separate systems for stormwater and sanitary sewers is the best practice to avoid overloading treatment plants, environmental contamination, and high treatment costs.

Following the Flow

Understanding the typical flow through the system helps identify components needing monitoring and maintenance. Wastewater exits properties through plumbing into sewer laterals, moves through junctions to sewer mains, and finally to treatment plants or outfalls. When gravity isn’t enough, pump stations lift water through force mains to its destination.

Why Make Sewer Inspections?

Aging sewer infrastructure can suffer from deterioration, blockages, overflows, diminished capacity, and more. Inspections and proactive maintenance help mitigate these issues. Common activities include inspecting lateral lines, sewer lines, junctions, connections, manholes, and pump stations, and monitoring force mains.

Factors contributing to pipe failure include surface weight, soil erosion, chemical interactions, increased water pressure, extreme temperatures, and untreated defects. Proactive inspections help prioritise, plan, and budget repairs, ensuring regulatory compliance, identifying issues early, and improving efficiency.

Regulatory Requirements

Awareness of regulatory requirements is crucial in the underground asset industry. These regulations cover water pollution, council and industrial standards, wastewater and stormwater guidelines, and authorised inspection bodies. Australia’s National Water Quality Management Strategy (NWQMS) provides guidelines for various water management types, which can be found on the Water Quality Australia website.

Consistent Standards for Reporting

Consistent standards in reporting sewer system conditions are vital for universal understanding. Pipeline assessment software like SECA’s WinCan helps categorise observations, enabling efficient data recording, analysis, and sharing. Standard formats include defect codes, severity, size, location, and more, aiding in identifying trends, prioritising maintenance, and budgeting.

Defects and Deterioration

Common sewer defects include tree roots, debris blockages, fats, oils, and grease (FOG), protruding traps, offset pipe joints, and sags. Other issues like sanitary sewer overflows (SSOs) and backups can cause environmental contamination and health hazards. Proactive inspection and cleaning are essential to prevent these problems.

Sewer Cleaning

Regular inspection and cleaning prevent sewer defects and deterioration. Cleaning methods include hydraulic, mechanical, and chemical/biological cleaning. Hydraulic cleaning uses water applications, mechanical cleaning employs physical devices, and chemical cleaning addresses odours, grease, root growth, and more.

Sewer Inspection

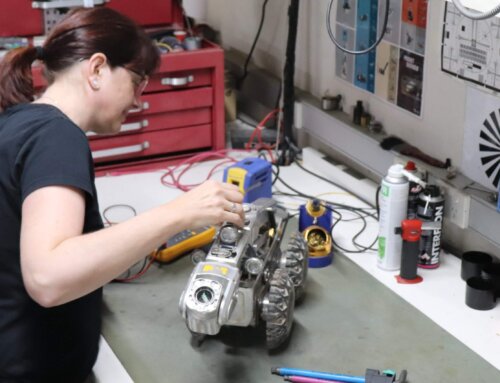

Routine inspections, both visual and non-visual, help identify potential issues before they become emergencies. Visual technologies like sewer crawlers, zo

om cameras, video nozzles, push cameras, digital scanners, and lateral launches offer detailed insights without needing physical entry. Non-visual technologies assess geometric changes, wall thickness, deformations, and ground conditions using acoustic systems, leak testing, laser profiling, ground-penetrating radar, and geospatial probes.

Sewer Repair and Rehabilitation

The final step in sewer maintenance is repair and rehabilitation, aiming to maintain or increase structural integrity, limit capacity issues, and protect the environment. Modern methods favour trenchless solutions over traditional excavation, minimising environmental and community impact. Techniques include pipe bursting, slip-lining, cured-in-place pipe (CIPP), deform/reform, mechanical point repair, injection methods, cement grout, spray lining, pipe reaming, and re-rounding.

By understanding and implementing these practices, asset owners can ensure their sewer systems operate efficiently, comply with regulations, and avoid costly emergencies. For more information and expert advice, contact us at [email protected] or 1800 028 584.

Download our comprehensive overview of sewer inspection and maintenance, helping asset owners stay ahead and maintain efficient, compliant, and environmentally safe sewer systems.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_btn title=”DOWNLOAD” color=”orange” align=”center” css=”” link=”url:https%3A%2F%2Fseca.com.au%2Fwp-content%2Fuploads%2F2023%2F10%2FSewer-Maintenance-101-WhitePaper-SECA.FINAL_.pdf|target:_blank”][/vc_column][/vc_row]