A Cleaning Guide for Sewer Crawlers

Posted by Kristel Hudson on 13-December-2023 10:11:26 Find me on: LinkedIn

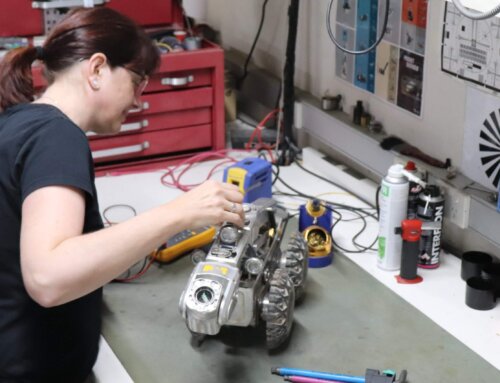

As you focus on maintaining operational efficiency, remember to prioritise the care of your trusted sewer crawler. Like any valued team member, your crawler requires proactive maintenance to ensure it remains a reliable asset in your operations. In this Cleaning Guide, we’ll outline essential steps to maintain your equipment effectively, promoting longevity and peak performance throughout the year.

Recognising the Value of Your Crawler

Your sewer crawler is more than just equipment; it’s a critical investment in your operational efficiency. Proactive Maintenance Routine Before you pause for maintenance, dedicate time to these essential tasks:

- Disassembly and Cleaning: Break down the crawler into its components and thoroughly clean each part with a toothbrush and soapy water. Regular cleaning prevents buildup and ensures optimal performance.

- Lubrication: Apply fresh lubricant to moving parts after cleaning to reduce friction and maintain smooth operation.

- Spacer and Screw Maintenance: Use cotton buds to clean spacers and screw holes, ensuring no debris remains. Lubricate screw holes to displace any moisture and prevent corrosion.

- Storage: Store all components in a well-organised toolbox to protect them from damage and simplify future inspections.

- Cable and Reel Care: Clean the cable with soapy water to remove dirt and ensure it rewinds smoothly without tangles. Wipe the reel’s drip tray and window for clear visibility during inspections.

- Truck Maintenance: Sweep and wipe down the truck’s interior to maintain cleanliness and functionality.

Semi-Annual Integrity Test

To verify the reliability of your crawler, conduct a semi-annual integrity test:

- Submersion Test: Submerge the crawler in soapy water to detect and address any leaks promptly.

- Component Sanitisation: Clean and sanitise each component post-test to ensure hygiene and prevent contamination.

Additional Maintenance Tips

Consider these extra touches to maintain equipment integrity:

- Truck Washdown: Give your truck a thorough wash to protect its exterior to enhance its appearance.

- Toolbox and Computer Maintenance: Clean and organise toolbox drawers and dust inside the computer for optimal functionality.

By investing time and effort into proactive maintenance, you’ll ensure a reliable and efficient sewer crawler year-round. Enhance equipment longevity and operational reliability through consistent care and attention.

Interested in establishing a proactive maintenance programme for your crawler? Download our FREE Crawler Maintenance Logbook to track cleaning, maintenance, and performance. Suitable for all brands, it fosters accountability and enhances equipment reliability. Download your copy today.