Breaking the reactive cycle

Why technology adoption is now the real driver of wastewater and asset network performance

Posted by Grant Brown SECA – Head of Sales and Marketing

Across Australia, councils and water authorities are facing the same challenge: ageing networks, rising community expectations, and budgets that never quite stretch far enough. For decades, reactive maintenance has been the default response to sewer issues but every emergency callout chips away at resources that should be invested in long-term asset renewal.

Asset owners understand this better than most. You’re trying to shift your organisation from “fixing what breaks” to building a smarter, safer and more cost-predictable network. Yet even when new equipment or systems are purchased with the best of intentions, one barrier consistently undermines progress: technology adoption at the operator level.

The truth is simple:

Reactive maintenance isn’t just a budgeting problem it’s an adoption problem. And the most successful councils are addressing both together.

The Hidden Cost of Staying Reactive

Emergency repairs feel unavoidable, but their true cost is often underestimated.

Beyond the obvious labour and equipment expenses, reactive maintenance drains operations in less visible ways:

- Crew mobilisation at short notice

- Traffic control and public disruption

- Safety risks under uncontrolled conditions

- Reputational impact during high-visibility failures

- Lost time that should have been spent inspecting and planning

Every reactive job steals capacity from preventative programs the very programs that would have reduced emergency events in the first place.

For many councils, the result is a cycle where deteriorating assets remain undetected until the point of failure. And while modern CCTV systems, jetting units and digital reporting tools promise better foresight, the benefits only materialise when crews feel confident using them.

The Hidden Cost of Staying Reactive

In our work with councils nationwide, the pattern is consistent: it’s rarely the technology that fails it’s the rollout.

Operators resist new tools for predictable and understandable reasons due to experience, lack of practical training and mixed fleets capability.

When adoption suffers, leadership doesn’t get the data or operational improvements they were counting on. Procurement starts to question value. The organisation retreats to reactive mode, not because it wants to, but because consistency across teams never fully took hold.

The frustration: the equipment is technically there, but the outcome isn’t.

How Leading Councils Are Breaking the Cycle

Across Australia, forward-thinking authorities are demonstrating that the shift from reactive to predictive maintenance isn’t just about buying better equipment it’s about designing adoption into the solution from day one.

The councils getting it right share three traits:

1. They standardise their fleet and workflows

Consistency reduces training time, improves operator confidence, and produces more reliable data for asset planning. Standardisation means fewer surprises, easier support, and clearer justification for long-term upgrades.

2. They invest in practical, ongoing operator training

Not just a demonstration on delivery, but refresher training, onboarding for new hires and real-world application. This turns technology from an obligation into a tool crews want to use.

3. They choose supplier partners not just products

High-performing councils engage suppliers who provide:

- Servicing

- Local parts and rapid turnaround

- Follow-up support

- Systems designed for adoption, not complexity

They treat suppliers as part of their asset management system, not just a transactional purchase.

SECA’s Role in Enabling Predictive, High-Confidence Operations

At SECA, our work with councils across Australia has shown that equipment alone is not enough. The real value comes from sustainable adoption and consistent performance across teams.

That’s why we support councils with:

- Robust, operator-friendly CCTV and jetting systems

- Hands-on training at delivery and ongoing refresher sessions

- Reliable service programs that preserve uptime

- Parts availability and rapid repairs

- Standardised workflows and documentation that integrate into procurement requirements

- Technology designed for simplicity and real-world reliability

When councils combine modern tools with strong adoption frameworks, they gain:

- Predictable budgets

- Reduced emergency callouts

- Safer work environments

- Better asset data

- Stronger internal confidence in asset decision-making

- Improved community outcomes

The shift from short-term fixes to long-term system performance should be the goal.

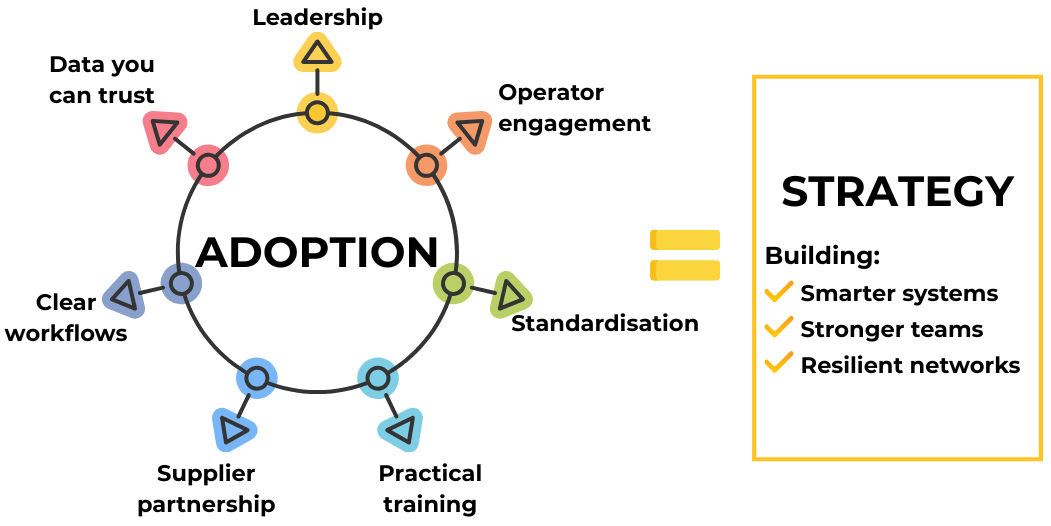

A Final Thought: Adoption is Strategy

The councils making the biggest leaps forward aren’t the ones spending the most they’re the ones ensuring their investments take root.

Moving from reactive to predictive maintenance requires more than new technology. It requires:

- Leadership

- Operator engagement

- Standardisation

- Practical training

- Supplier partnership

- Clear workflows

- Data you can trust

When these elements come together, the transformation is profound: fewer surprises, fewer headlines, and a network that performs the way a modern council needs it to.

At SECA, we’re proud to support the councils building smarter systems, stronger teams, and more resilient networks.

Because the future of wastewater asset management isn’t reactive or even preventative, it’s predictable, reliable and adopted across the entire organisation.